Sourcing the perfect insulated backpack is often a balancing act. You are likely staring at three different quotes from three different suppliers, and the price per unit varies wildly. On the surface, the bags might look similar—same color, same shape, same capacity. So, why does one cost $8 and another $25?

For procurement managers and business owners, the “sticker price” is just the tip of the iceberg. The final cost is a complex aggregate of raw material science, ergonomic engineering, manufacturing volume, and logistical realities. Understanding these variables is the only way to negotiate effectively and ensure you aren’t paying for features you don’t need—or worse, buying a cheap product that will fail your customers.

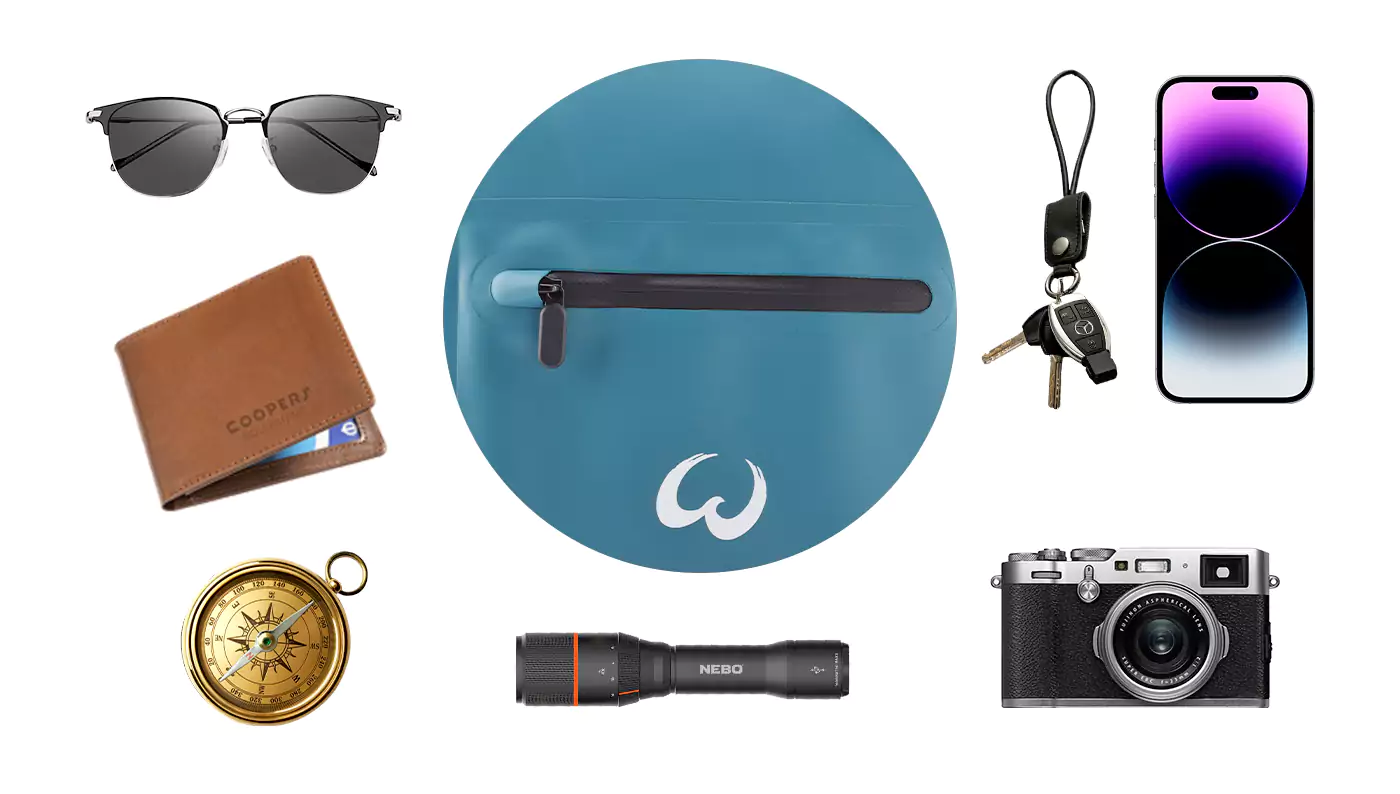

Whether you are a retailer looking for a summer hit or a corporation sourcing employee gifts, navigating the pricing structure of a cooler backpack distributor requires a look under the hood. In this guide, we will break down the five distinct levers that drive costs, with insights into how industry veterans like weierken manage these factors to deliver value.

1. Insulation Performance: Materials and Technical Solutions

The primary function of a cooler backpack is to keep things cold. Consequently, the “thermal engine”—the insulation layer—is often the single biggest cost driver. A cooler backpack distributor prices their products based on thermal physics, not just aesthetics.

The Hierarchy of Core Materials

Not all foams are created equal. The raw material you choose determines the baseline pricing tier.

- Entry-Level (PE Foam): This is the most common material for budget-friendly promotional bags. Polyethylene (PE) foam is lightweight and cheap to produce. It offers decent insulation for short trips (2-4 hours), but it lacks density. If your target market is casual picnic-goers, this keeps the price low.

- Mid-Range (High-Density NBR/PU): As you move up the price ladder, you encounter NBR (Nitrile Butadiene Rubber) or high-density PU (Polyurethane) foam. These materials are denser, offering better thermal resistance and a more premium, “squishy” feel. They require more expensive chemical precursors and slower production processes, which raises the wholesale price.

- High-Performance (VIP & PCM): At the top tier, you have Vacuum Insulation Panels (VIP) and Phase Change Materials (PCM). These are often used in medical-grade or high-end outdoor gear. VIPs offer insulation values 5-10 times higher than traditional foam but are fragile and expensive to integrate. PCMs can actively regulate temperature (keeping items at exactly 5°C, for example). If your cooler backpack distributor is quoting you for these, expect a significantly higher unit cost.

Technical Integration and Smart Features

Beyond the foam, technology adds layers of cost. A standard “drop-in” liner is cheap. However, if you require a leak-proof, high-frequency welded TPU liner (which eliminates stitching holes), the machinery required is expensive. Furthermore, modern trends like integrated smart temperature displays, solar panels on the outer shell, or built-in rapid-freezing boards will drastically widen the price gap compared to a standard model.

2. Ergonomic Design and Structural Complexity

A cooler backpack is unique because it is a hybrid product: it is half cooler, half hiking pack. When full, these bags are heavy. A 20-liter cooler filled with ice and beverages can weigh over 15kg. This brings us to the second major price factor: how the bag carries that weight.

The Cost of the Suspension System

A cheap cooler backpack will have simple webbing straps. A premium one will have an engineered suspension system.

- Shoulder Straps: To handle the weight, straps need to be padded with EVA foam and covered in breathable air-mesh. Constructing a contoured, ergonomic strap takes three times longer on the sewing floor than a flat strap.

- Back Panels: High-end models feature molded back panels with airflow channels to prevent the user’s back from sweating. This requires specialized molding equipment and additional materials.

- Load Distribution: The addition of sternum straps (chest clips) and load-bearing hip belts adds to the bill of materials (BOM) and labor time.

Structural Details and Hardware

A cooler backpack distributor also factors in the durability of the components.

- Zippers: A standard nylon zipper is cents on the dollar. However, a cooler backpack often requires an airtight or watertight zipper (like a TIZIP style) to prevent cold air from escaping and melted ice from leaking. These specialized zippers are expensive and difficult to install.

- Fabric Durability: Are you using 600D Polyester (standard) or 840D TPU-coated Nylon (waterproof and puncture-resistant)? The latter is significantly more expensive but necessary for rugged outdoor environments.

- Reinforcement: Heavy loads require “bar-tack” stitching at stress points. This extra reinforcement ensures the strap doesn’t rip off when the bag is full, but it adds seconds to the production time of every unit—costs that accumulate over thousands of bags.

3. Degree of Customization and Service Models

The gap between buying a “stock” product and a “custom” product is one of the most misunderstood aspects of B2B pricing. The level of intervention you require from the cooler backpack distributor dictates the pricing structure.

Basic Customization (Light OEM)

If you select a pre-existing model from the distributor’s catalog and simply want to add your logo or change the fabric color, the price impact is minimal.

- Logo Implementation: Screen printing, heat transfer, or rubber patches are standard procedures.

- Color Ways: As long as you meet the fabric mill’s minimums, changing the color of the main body usually doesn’t incur extra fees.

Functional Customization

Price increases occur when you start moving pockets, adding dividers, or requesting specific features that alter the sewing pattern.

- Pattern Making: Changing the dimensions of the cooler compartment requires the factory to create new paper patterns and cutting dies.

- Mold Fees: If you want a custom plastic handle, a branded zipper puller, or a hard-shell bottom, you will have to pay for the mold. These are one-time fees (often ranging from $500 to $5,000) that must be amortized over your order quantity.

Full ODM (Original Design Manufacturing)

If you come to a partner like weierken with a sketch on a napkin and ask for a completely new invention, you are entering ODM territory. This involves R&D teams, prototyping rounds, and field testing. The distributor isn’t just selling you a bag; they are selling you their engineering time. Consequently, ODM projects usually come with higher Minimum Order Quantities (MOQs) and a higher per-unit price to cover the development overhead.

4. Order Scale and Relationship Strength

It is a universal rule in manufacturing: volume drives value. However, the nuances of how volume affects price are worth noting.

The “MOQ” Cliff

Factories run on momentum. Setting up the production line—threading the machines, calibrating the die-cutters, mixing the raw materials—costs the same whether you produce 500 backpacks or 5,000.

- Small Batches: If you order below the MOQ, the cooler backpack distributor often applies a surcharge to cover the “downtime” of switching the line for a small run.

- Tiered Pricing: Most distributors offer clear breaks. The difference between 1,000 units and 3,000 units can be substantial because the latter allows the factory to buy fabric and foam in bulk rolls rather than cut yardage, lowering their input costs.

The Value of Partnership

Relationships matter. A one-off order is priced differently than a long-term contract.

- Framework Agreements: If you can commit to purchasing 20,000 units over a year, but only need 5,000 delivered quarterly, a strong distributor will often honor the 20,000-unit price tier.

- Payment Terms: Suppliers are essentially acting as banks. If you pay 100% upfront, you have high bargaining power. If you require “Net 60” payment terms, the distributor may slightly pad the unit price to cover their cash flow interest and risk.

- VMI (Vendor Managed Inventory): Some advanced distributors offer to hold stock for you. While this increases the unit price (to cover warehousing), it frees up your cash flow and storage space, which might be a net positive for your business.

5. Supply Chain Layout and Comprehensive Logistics

The final price on your invoice depends heavily on where the backpack is made and how it gets to you. Smart buyers look at the “Landed Cost” rather than just the “Ex-Factory” price.

Origin and Tariffs

Labor costs in Southeast Asia might be lower than in other regions, but you must factor in the geopolitical landscape. Import duties and tariffs can turn a cheap backpack into an expensive one overnight. A global cooler backpack distributor often has diversified production bases to help clients navigate these tariffs.

Incoterms: Who Pays for What?

The acronyms on your quote sheet (EXW, FOB, CIF, DDP) fundamentally change the cost structure.

- EXW (Ex Works): You pay the factory price, but you must arrange pickup, export clearance, and shipping. It looks like the lowest price, but it carries the highest administrative burden and risk for you.

- FOB (Free on Board): The standard. The distributor covers costs until the goods are on the ship.

- DDP (Delivered Duty Paid): The distributor handles everything right to your warehouse door. This price is higher, but it protects you from fluctuating shipping rates and surprise customs fees.

Logistics and Speed

Does the distributor have a warehouse in your country? Shipping from a local warehouse (even if the goods were originally made overseas) cuts delivery time from weeks to days. This convenience is a value-added service that is often reflected in the wholesale price.

When you receive a quote from a cooler backpack distributor, look beyond the bottom line. Ask yourself: Is the insulation suitable for my use case? Is the harness system designed for human comfort? Am I paying for necessary customization or unnecessary complexity?

The goal isn’t always to find the cheapest bag; it is to find the bag that offers the best margin for your business while maintaining your brand’s reputation for quality. A cheap bag that leaks or hurts to wear will cost you more in returns and bad reviews than you saved in procurement.

This is why partnering with an experienced manufacturer like weierken is crucial. By transparently discussing these five factors—materials, design, customization, volume, and logistics—we help you engineer a product that fits both your budget and your performance requirements.

FAQ: Questions for Your Cooler Backpack Distributor

Q1: What is the standard Minimum Order Quantity (MOQ) for a custom cooler backpack?

A1: The MOQ typically depends on the level of customization. For a standard model with just a logo change, a cooler backpack distributor might accept 500 units. For a fully custom design (ODM) requiring specific fabric colors and custom molds, the MOQ is usually between 1,000 and 3,000 units to ensure material efficiency.

Q2: How does a “welded” cooler backpack differ in price from a “sewn” one?

A2: Welded backpacks (using High-Frequency welding technology) are significantly more expensive—often 30% to 50% higher. This is because they use specialized TPU materials and require expensive welding machinery rather than standard sewing machines. However, they offer 100% waterproof and airtight performance, which sewn bags cannot guarantee.

Q3: Can I get a sample before placing a bulk wholesale order?

A3: Yes, reputable distributors always provide samples. Expect to pay a sampling fee (which covers the pattern maker’s time and materials). This fee is often refundable or credited towards your deposit once you place a bulk order that meets the MOQ.

Q4: Which insulation material provides the best value for money?

A4: For most general consumer applications (picnics, grocery shopping, beach days), High-Density PE foam (EPE) or NBR foam offers the best balance of performance and cost. It is durable, flexible, and keeps items cold for 6-12 hours with ice packs. VIPs are generally overkill for consumer backpacks unless you are transporting medical supplies.

Q5: What are the typical lead times for manufacturing cooler backpacks?

A5: After sample approval, mass production generally takes 35 to 50 days. This allows time for material procurement, cutting, sewing, and quality inspection. Shipping (ocean freight) can add another 30-45 days depending on your location. Always plan your inventory at least 3 to 4 months in advance.

Ready to start your next project?

Stop guessing about costs and start planning for success. Contact Weierken today to discuss your cooler backpack requirements and get a detailed quote tailored to your business needs.

[Click Here to Send an Inquiry]