If you’re a procurement manager, brand owner, or supply chain specialist in the food or retail sector, choosing the right custom cooler bag isn’t just another task—it’s a strategic decision. Your insulated delivery bags directly affect product freshness, delivery efficiency, and how customers perceive your brand.

We’ve combined key insights from industry use-cases and manufacturer evaluation into one actionable guide—helping you source high-performing, reliable cooler bags from a partner you can trust.

Which Industry Do You Operate In?

Different food sectors have unique temperature and design needs. Before you start comparing manufacturers, clarify your core use case:

Chain Restaurants & QSRs

You need bags that keep hot food above 60°C for 2+ hours and cold items below 5°C for 4+ hours. Look for leak-proof zippers, easy-to-clean liners, and durable construction for daily reuse.

Frozen Food & Seafood Distributors

Your priority is sub-zero temperature control for 4–12 hours. Puncture-resistant bases, waterproof materials, and FDA/REACH certified liners are essential.

High-End Patisseries & Specialty Cafés

You transport sensitive items like cakes and chocolates. Focus on precision temperature control (2–8°C), crush-proof panels, and high-definition branding.

E-Grocery & Meal Kit Services

You need lightweight, cost-effective, and reusable cooler bags that also act as brand billboards. Modular designs that stack easily in delivery vehicles are a plus.

The Science Behind Effective Cooler Bags: Material and Construction Insights

Understanding the technical components of insulated bags will empower you to make smarter sourcing decisions and have more productive conversations with manufacturers.

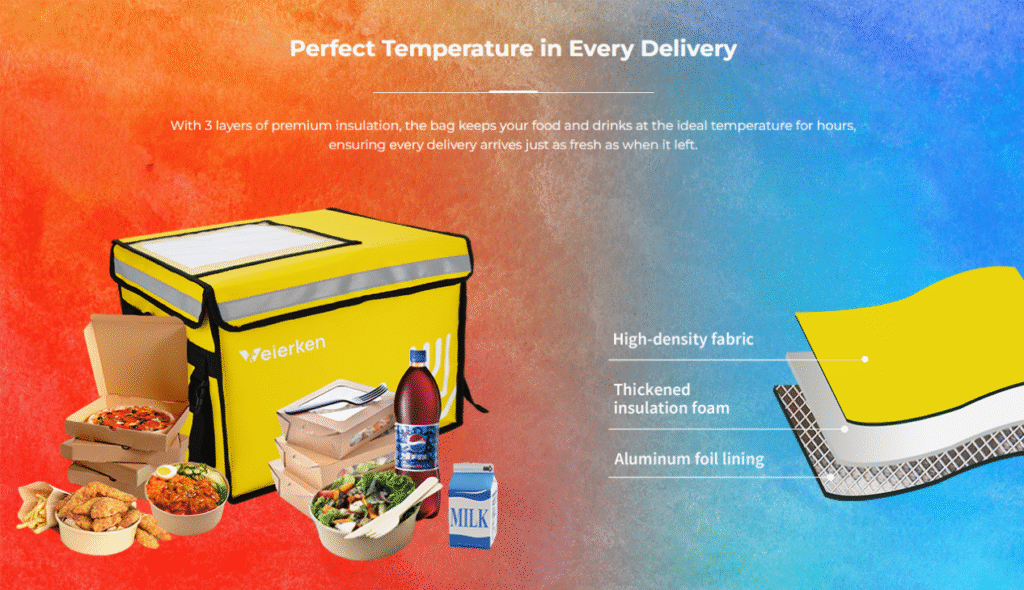

Insulation Technologies Explained

The core of temperature protection lies in the insulation materials:

EVA Foam Layers: Closed-cell ethylene-vinyl acetate foam provides excellent thermal resistance with moisture-proof properties. Higher density foams (45-60kg/m³) offer superior insulation but increase weight and cost.

Reflective Barriers: Aluminum foil laminates reflect radiant heat, significantly enhancing temperature retention in both hot and cold environments.

Non-Woven Fiberfill: Recycled PET fiberfill offers eco-friendly insulation with good compression recovery, maintaining performance even after repeated use.

Advanced Fabric Constructions

Exterior Layers: 600D polyester fabrics provide optimal durability for daily use, while 420D nylon offers a lighter weight alternative. PVC-backed materials deliver complete waterproofing for challenging weather conditions.

Interior Liners: FDA-compliant PEVA (polyethylene vinyl acetate) liners offer odor resistance and easy cleaning, while TPU (thermoplastic polyurethane) liners provide superior flexibility at low temperatures.

Closure Systems and Thermal Integrity

The weakest point in any insulated bag is typically the closure system. Look for:

Magnetic Seals: Create an airtight closure that minimizes temperature exchange

Double-Zipper Designs: Allow for partial opening while maintaining temperature in unused compartments

Thermal Bridge Breaks: Insulated zipper flaps that prevent heat transfer through metal components

5 Key Factors When Choosing a Cooler Bag Manufacturer

Once you know your operational needs, use this checklist to assess potential suppliers:

1. Customization & Design Support

Your manufacturer should operate as a seamless extension of your team, combining technical expertise with creative collaboration. Key capabilities to prioritize include:

OEM/ODM Capabilities: A proficient partner should offer comprehensive OEM services for branding existing designs and ODM support for developing unique products from scratch. This includes structural engineering, material selection, and functional feature integration tailored to your brand’s requirements.

Market-Led Design Input: Suppliers with dedicated R&D teams can provide actionable insights based on consumer trends, competitor analysis, and regional market preferences. For example, they might recommend lightweight insulation for urban commuters or heavy-duty waterproof zippers for outdoor adventure lines.

Fast Prototyping and Sampling: Look for manufacturers that streamline the prototyping process with clear timelines (e.g., 7–10 days for initial samples). Iterative sampling ensures design flaws are addressed early, saving costs and accelerating time-to-market.

2. Sustainability & Material Compliance

As environmental regulations tighten and consumer preferences shift, a credible manufacturer must demonstrate transparency and commitment to sustainability. Critical areas to evaluate include:

RPET and Recycled Material Options: Suppliers should offer fabrics made from post-consumer recycled materials (e.g., GRS-certified RPET) and provide documentation to validate recycled content claims.

GRS, REACH & BSCI Certifications: GRS (Global Recycled Standard) ensures traceability of recycled materials, while REACH compliance guarantees products are free from hazardous chemicals. BSCI certification reflects adherence to ethical labor practices, increasingly required by global retailers.

End-of-Life Recycling Programs: Forward-thinking manufacturers now take back production waste or offer take-back programs for end-of-life products, supporting circular economy initiatives.

3. Production Capacity & Lead Times

A reliable production partner must balance flexibility with scalability, especially during high-demand periods. Key verification points include:

Scalable Production for Large Orders: Ensure the supplier can ramp up production seamlessly, whether you need 5,000 units for a regional promotion or 100,000 for a nationwide campaign. Inquire about their factory capacity, subcontracting policies, and quality control measures at scale.

Proven Peak-Season Performance: Manufacturers with experience in seasonal industries (e.g., summer coolers or holiday gift sets) should have contingency plans for raw material shortages and logistics bottlenecks.

Clear Lead Times (Typically 25–65 Days): Transparent timelines should cover material sourcing, production, quality checks, and shipping. For example, standard OEM orders may take 25–35 days, while complex ODM projects with custom tooling could require 50–65 days.

4. Quality & Certifications

Product quality directly impacts brand reputation and customer satisfaction. Insist on the following:

ISO 9001 Certification: This internationally recognized quality management standard ensures consistent processes, from raw material inspection to final packaging.

FDA-Compliant Food-Grade Materials: For cooler bags storing perishables, liners must meet FDA standards to prevent chemical migration and ensure food safety.

Third-Party Thermal Performance Testing: Independent lab tests (e.g., ASTM D3103) validate insulation claims, such as maintaining temperatures below 40°F for 4–6 hours. Additional testing for zipper durability, seam strength, and waterproofing (IPX4+) may also be relevant.

5. Industry-Specific Expertise

A manufacturer’s familiarity with your niche can drastically reduce onboarding time and design errors. Evaluate their experience in sectors like:

Pizza Delivery: Requires heat-retention testing, grease-resistant liners, and stackable designs.

Frozen Seafood: Demands robust leak-proof construction, odor-resistant materials, and compliance with cold-chain logistics standards.

Gourmet Meal Kits: Prioritizes aesthetic appeal, compartmentalization, and eco-friendly branding to align with premium consumer expectations.

Technical Specifications: What the Numbers Really Mean

When reviewing Cooler Bag manufacturers specifications, these are the critical metrics that matter:

Temperature Retention Performance

Cold Retention: Measured in hours at specific external temperatures (e.g., maintains 0-4°C for 6 hours at 30°C ambient)

Heat Retention: Typically shorter duration than cold retention due to faster heat transfer dynamics

Real-World Testing: Look for field testing data, not just laboratory conditions

Durability Standards

Zipper Cycle Testing: Quality zippers should withstand 10,000+ open/close cycles

Carrying Handle Strength: Rated for 3-5x expected maximum load weight

Abrasion Resistance: Martindale or Wyzenbeek test results for exterior fabrics

Seam Strength: Tensile testing data for stitched and welded seams

Why the Right Partner Matters More Than Just the Product

A reliable cooler bag manufacturer does more than produce—they collaborate. They help you optimize designs, ensure on-time delivery, and maintain consistent quality.

For example, Weierken offers:

End-to-end OEM/ODM cooler bag solutions

Sustainable material options including RPET fabrics

Certifications like ISO 9001, BSCI, FDA, and GRS

Industry-specific thermal packaging expertise

Your Next Steps

Ready to find a supplier that fits your brand and operational needs?

1.Define your specs—temperature, capacity, material, budget

2.Request samples—test for durability, insulation, and branding quality

3.Ask for certifications and lead times

4.Start with a trial order

Frequently Asked Questions

1. What is the realistic temperature retention I can expect from a standard custom cooler bag?

Temperature retention varies by design and materials, but high-quality bags typically maintain internal temperatures within a safe range for 2-6 hours. For cold items, expect maintenance of 0-4°C for 4+ hours in 30°C ambient temperature. Hot food generally stays above 60°C for 2-3 hours. Specific performance depends on factors like insulation thickness, ambient conditions, pre-conditioning of thermal packs, and how frequently the bag is opened.

2. Are there food-safe materials that are also environmentally friendly?

Yes, several sustainable options meet food safety standards. RPET (recycled polyethylene terephthalate) fabrics made from post-consumer plastic bottles offer durability with recycled content. PEVA and TPU liners provide FDA-compliant food contact surfaces without PVC. Water-based inks and solvent-free lamination processes reduce chemical usage while maintaining food-grade safety standards.

3. What is the typical minimum order quantity for custom cooler bags?

MOQs depend on customization level. For basic branding on standard designs, MOQs typically start at 500-1,000 units. For custom sizes and materials, expect 1,000-2,500 units. Fully custom designs from scratch usually require 2,500-5,000 units. Some manufacturers offer lower MOQ programs with modular component systems that allow customization without full custom tooling.

4. How long does the development process take from concept to production?

The complete process typically takes 8-12 weeks. This includes 2-3 weeks for design finalization and prototyping, 1-2 weeks for sample testing and revisions, and 4-6 weeks for production after sample approval. Complex custom designs may require additional time for tooling and material sourcing. Always build in buffer time for testing and quality validation before your launch date.

5. What certifications should I prioritize for food delivery applications?

The essential certifications include FDA compliance for food-contact materials, ISO 9001 for quality management systems, and BSCI for social compliance. For environmental claims, GRS certification validates recycled content. Depending on your markets, REACH compliance may be necessary for chemical safety. Some manufacturers also offer ISO 14001 for environmental management systems.

Don’t just buy a bag—build a partnership. The right custom insulated delivery bag supplier will help protect your product, amplify your brand, and support your growth.

Looking for a reliable cooler bag manufacturer?

Contact us today to request samples, discuss your needs, and get a tailored quote.