When corporate procurement managers evaluate promotional products, they’re not just buying items—they’re investing in mobile brand touchpoints. OEM cooler bag manufacturing represents a sophisticated segment where practical utility meets marketing strategy. Unlike standard off-the-shelf options, custom cooler bags serve as walking billboards at beach events, corporate picnics, retail promotions, and outdoor activations. The fundamental challenge isn’t recognizing their value, but navigating the complexities of cooler bag manufacturing to ensure final products reflect brand standards while meeting functional demands. This is where technical expertise in OEM cooler bag production separates exceptional suppliers from basic manufacturers.

The Technical Foundation: Materials and Construction Methods

Advanced Material Selection for Performance Applications

The material specification forms the foundation of any successful cooler bag manufacturing project. Professional manufacturers like Weierken typically work with a spectrum of technical materials, each serving distinct market segments:

Insulated Polyester with PEVA Lamination: The industry standard for food-grade applications, offering reliable thermal performance and moisture resistance. Typically features 5-8mm EPE foam insulation for basic temperature retention.

600D Polyester with PVC Backing: Superior abrasion resistance makes this ideal for rugged outdoor use. The high-denier fabric withstands repeated packing and transportation while maintaining structural integrity.

RPET Fabrics with GRS Certification: The growing demand for sustainable branding has made recycled materials increasingly popular. RPET cooler bags demonstrate corporate environmental commitment while maintaining performance standards.

Non-Woven PP (NWPP): A cost-effective solution for short-term promotional campaigns, though with limited durability compared to woven alternatives.

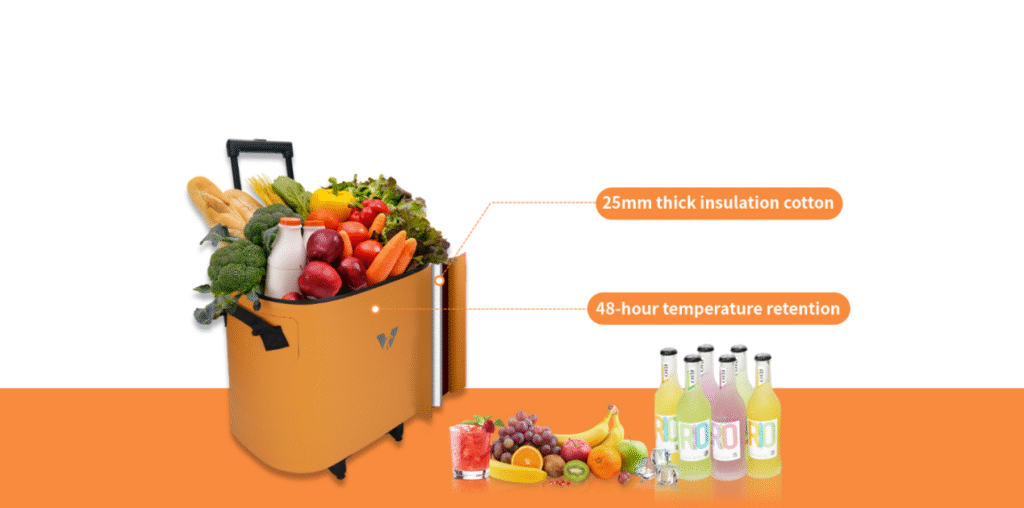

Hard-Sided Cooler Construction: Utilizing rotational molding for seamless PE construction or injection molding for precise PP components, these represent the premium segment with superior ice retention capabilities.

Precision Manufacturing Techniques

The construction method directly impacts both durability and waterproof performance:

RF (Radio Frequency) Welding: Creates seamless, waterproof bonds by molecularly fusing material layers. Essential for premium OEM cooler bag production where leak-proof performance is non-negotiable.

Ultrasonic Welding: Used for specific synthetic materials where traditional stitching would compromise waterproofing.

Reinforced Stitching with Seam Taping: Combines traditional sewing strength with waterproof tape applications for balanced performance and cost-efficiency.

Bar Tack Reinforcements: Critical stress points like handle attachments and strap connections require this specialized stitching to prevent failure under load.

The OEM Development Process: From Concept to Delivery

Collaborative R&D and Market-Focused Design

True OEM cooler bag manufacturing operates as an extension of your product development team. The process begins with technical consultation addressing specific use cases:

Thermal Performance Requirements: Will the bags transport frozen goods, beverages, or pharmaceuticals? This determines insulation thickness and closure systems.

Carrying Configuration Analysis: Shoulder straps, backpack style, or tote handles? Each serves different demographic preferences and usage scenarios.

Brand Integration Strategy: How will logos and graphics be applied while maintaining material performance and aesthetic appeal?

Weierken’s design team typically engages in 2-3 prototyping iterations, refining everything from zipper selection to internal organization features before finalizing production specifications.

Compliance Infrastructure and Quality Assurance

Global marketing initiatives demand rigorous compliance frameworks. Professional cooler bag manufacturing partners maintain:

ISO 9001:2015 Certification: Ensures consistent quality management systems throughout production.

BSCI Social Compliance Audit: Verifies ethical manufacturing practices for corporate social responsibility reporting.

REACH Chemical Compliance: Mandatory for European market distribution, ensuring material safety.

FDA Compliance: Essential for food-contact applications, particularly important for cooler bag liners.

GRS (Global Recycled Standard) Certification: Validates recycled content claims for sustainability-focused branding.

Production Capacity and Supply Chain Management

Realistic Lead Time Planning

Seasoned procurement professionals understand that quality manufacturing requires adequate timelines. For OEM cooler bag projects, standard production cycles typically span:

Standard Customization: 25-35 days for modifying existing designs with new graphics or colors.

Full Custom ODM Development: 50-65 days for completely new designs requiring tooling, extensive sampling, and complex material sourcing.

Scalability and Peak Season Management

The true test of a manufacturing partnership emerges during high-demand periods. Established manufacturers implement proactive capacity planning with dedicated production lines for urgent replenishment orders. This ensures promotional timelines aren’t compromised during critical marketing windows. Weierken maintains flexible production scheduling to accommodate both planned programs and last-minute opportunities.

Beyond Coolers: Complementary Product Sourcing

Strategic procurement managers often leverage manufacturing relationships across multiple product categories. While developing OEM cooler bag programs, many brands simultaneously explore waist pack wholesale opportunities from the same supplier. This consolidated approach streamlines logistics, ensures brand consistency across products, and often achieves volume pricing advantages through combined ordering.

Manufacturing Partnership as Competitive Advantage

In an era of supply chain volatility and increasing quality expectations, the manufacturer you select becomes a strategic pillar of your brand’s operational integrity. Beyond the transactional aspects of cost and lead time, a deeply integrated partner provides proactive value that safeguards your marketing investments. This includes early warnings on material availability shifts, data-driven recommendations for cost optimization without compromising quality, and engineering support to enhance product lifespan. For instance, a supplier’s insight might lead to reinforcing a stress point common in delivery bags, significantly reducing warranty claims and protecting brand reputation. This level of collaboration transforms the manufacturer from a mere executor into a strategic asset, enabling you to launch campaigns with confidence, navigate market fluctuations, and deliver a superior product experience that fosters customer loyalty. The reliability, innovation, and problem-solving capabilities of a partner like Weierken thus translate directly into a more resilient and competitive brand in the marketplace.

The evolution from vendor to strategic partner manifests most clearly when confronting industry-specific challenges. Consider the meal kit delivery sector, where thermal performance consistency directly impacts customer satisfaction and retention. A basic supplier might simply assemble bags to specification, while a strategic partner conducts real-world simulation testing, tracking internal temperatures across various transit durations and external conditions. They might recommend switching from standard EPE foam to cross-linked PE foam insulation—a modification adding minimal cost but extending effective cooling duration by 30-40%, directly reducing product spoilage rates. Similarly, for pharmaceutical logistics, a partner well-versed in FDA compliance doesn’t just use approved materials; they implement batch-level documentation and traceability protocols, creating an auditable trail that simplifies regulatory approval processes for your brand.

This partnership advantage extends into cost management in ways that transcend initial unit price negotiations. An experienced manufacturer brings value engineering expertise to the table, identifying opportunities to reduce material waste through pattern optimization or suggesting alternative component sources that maintain performance while lowering overall cost. For example, they might demonstrate how a slight adjustment to a bag’s gusset design maintains the same storage capacity while reducing fabric consumption by 8-10%—savings that compound significantly across a 10,000-unit order. Furthermore, their familiarity with international logistics can prevent costly shipping errors; they might advise on optimal carton dimensions that maximize container utilization or recommend packaging materials that withstand humidity fluctuations during ocean transit, avoiding water damage claims.

The most forward-thinking manufacturing partnerships now also address circular economy objectives. Rather than simply fulfilling orders, strategic partners help brands develop take-back programs for end-of-life products or integrate recycled content in ways that align with brand storytelling. A manufacturer might facilitate the recycling of production scrap into new accessory items like ice packs or utensil sets, creating a cohesive, sustainable product ecosystem. This holistic approach to product lifecycle management not only strengthens environmental credentials but also builds deeper emotional connections with environmentally conscious consumers, turning a practical cooler bag into a symbol of corporate responsibility.

OEM Cooler Bag Manufacturing: Frequently Asked Questions

What minimum order quantities apply to custom cooler bag programs?

Our standard MOQ for new OEM cooler bag designs begins at 500 units. However, we recognize that market testing and specialized applications may require flexibility. We regularly collaborate with brands to develop viable solutions for pilot programs while maintaining production efficiency.

How does your design process incorporate our specific brand requirements?

Our OEM/ODM services include comprehensive design collaboration. We analyze your brand guidelines, target audience, and usage scenarios to recommend materials, configurations, and branding applications that align with both your aesthetic standards and functional requirements.

What sustainable material options are available beyond standard fabrics?

Beyond GRS-certified RPET, we offer multiple eco-conscious alternatives including recycled PEVA insulation, water-based printing inks, and biodegradable packaging components. Our technical team can guide you through the performance characteristics and cost implications of each option.

How do you manage quality control throughout the manufacturing process?

Our ISO 9001 certified quality management system implements checkpoints at material intake, production line assembly, and pre-shipment inspection. This includes specific testing for insulation efficiency, seam strength, zipper durability, and graphic application quality.

What logistics support do you provide after manufacturing completion?

We offer comprehensive logistics coordination including commercial invoice preparation, customs documentation, and coordination with global freight partners. Our experience spans FOB, EXW, and CIF arrangements to match your existing supply chain preferences.

Manufacturing Partnership as Competitive Advantage

Successful ODM cooler bag manufacturing transcends simple production—it represents a strategic collaboration that impacts brand perception, marketing effectiveness, and operational efficiency. The distinction between adequate and exceptional lies in the manufacturer’s technical expertise, compliance infrastructure, and production reliability. These fundamental differentiators enable brands to execute flawless promotional campaigns and corporate gifting programs with confidence.