In an era where experiential marketing and practicality drive consumer engagement, oem cooler bag solutions have become a game-changer for businesses seeking to enhance brand visibility. From corporate events and outdoor promotions to retail giveaways, custom cooler bags offer a functional and memorable way to connect with audiences. However, the journey from concept to delivery involves navigating complexities like material selection, compliance standards, and scalable production—pain points that can derail even the most well-intentioned campaigns. As a trusted industry leader, Weierken specializes in addressing these challenges through end-to-end OEM cooler bag manufacturing, ensuring your brand stands out with precision-engineered products. This guide delves into the intricacies of oem cooler bag production, highlighting how Weierken’s expertise transforms ideas into impactful marketing assets.

Understanding OEM Manufacturing for Cooler Bags

OEM (Original Equipment Manufacturer) cooler bag production involves partnering with a specialized factory to design and manufacture bespoke bags aligned with your brand’s specifications. Unlike off-the-shelf options, oem cooler bag projects require collaboration on every detail—from insulation performance and material durability to branding aesthetics. For instance, a beverage company might need leak-proof, hard-sided coolers for beach promotions, while a healthcare brand could require FDA-compliant soft coolers for pharmaceutical samples. Weierken streamlines this process by integrating client input with industrial expertise, ensuring each custom cooler bag meets functional and promotional goals.

Why Invest in OEM Cooler Bags? Addressing Industry Pain Points

Businesses across sectors face common challenges when sourcing promotional products:

Inconsistent Quality: Subpar stitching or weak insulation leads to customer dissatisfaction.

Limited Customization: Generic designs fail to reflect brand identity.

Supply Chain Delays: Missed deadlines during peak seasons (e.g., summer campaigns or holiday events).

Compliance Gaps: Non-compliance with environmental or safety standards risks reputational damage.

OEM cooler bag manufacturing tackles these issues by offering tailored solutions. For example, Weierken’s clients have leveraged custom cooler bags for:

Corporate Gifting: Durable, logo-embellished bags for employee wellness kits.

Retail Promotions: Insulated totes as purchase incentives for grocery chains.

Event Marketing: Compact, hard-sided coolers for outdoor festivals or sports sponsorships.

Key Considerations in OEM Cooler Bag Production

R&D Capabilities: From Concept to Reality

A robust R&D process is critical for creating high-performance oem cooler bag designs. Weierken’s approach includes:

Market Research: Analyzing trends (e.g., demand for eco-friendly materials) to inform design.

Design Support: CAD prototyping and 3D rendering for visualizing bag structure, pockets, and closures.

Sampling Iterations: Producing multiple prototypes to test functionality, such as zipper durability or ice-retention rates.

OEM/ODM Flexibility: Adapting to client-led designs (OEM) or offering turnkey solutions (ODM).

Material Selection: Balancing Function and Sustainability

Choosing the right material impacts insulation, durability, and brand perception. Weierken provides options like:

Non-Woven PP: Lightweight and cost-effective for short-term promotions.

Polyester and Ribstop Nylon: Tear-resistant and ideal for outdoor use.

RPET (Recycled PET): Made from post-consumer plastic, aligning with circular economy goals.

PU-Coated Fabrics: Water-repellent for beach or picnic scenarios.

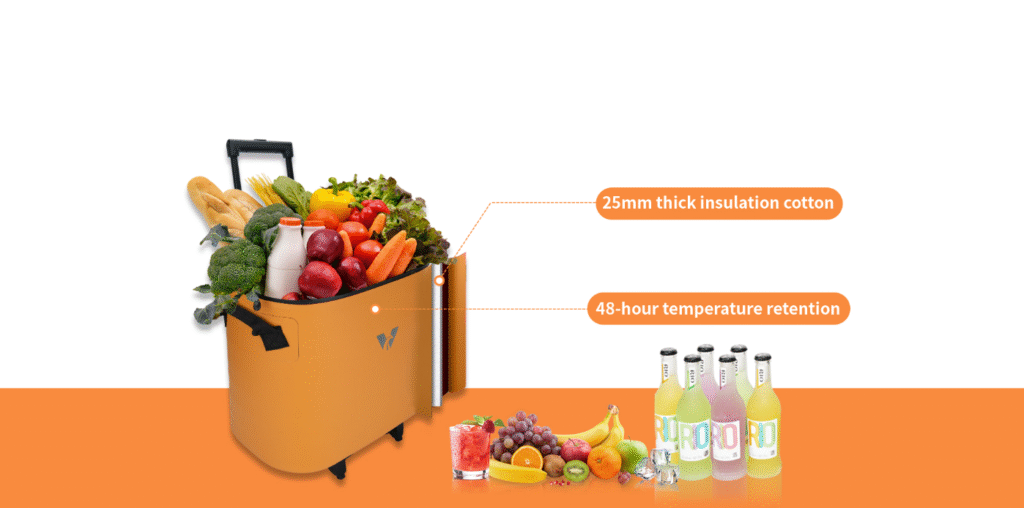

Hard-Sided Plastic: Superior ice retention for extended events.

Customization and Branding Techniques

Oem cooler bag projects thrive on personalization. Weierken employs:

Screen Printing: Vibrant logos for large-scale designs.

Embroidery: Premium finishes for corporate gifts.

Heat Transfer Designs: Complex graphics without compromising fabric integrity.

Adjustable Straps and Compartments: Enhancing usability for specific use-cases like hiking or grocery runs.

Quality Assurance and Testing

To prevent defects, Weierken implements:

Durability Checks: Stress tests on straps, zippers, and seams.

Insulation Performance: Measuring temperature retention over 6–12 hours.

FDA Compliance: Ensuring food-safe liners for coolers storing edibles.

Certifications: Adherence to ISO 9001 for quality management and BSCI for social accountability.

Environmental Compliance and Sustainability

With rising demand for eco-conscious products, Weierken integrates:

GRS (Global Recycled Standard): Certifying RPET and recycled material usage.

REACH Compliance: Eliminating hazardous chemicals in dyes and coatings.

Sustainable Practices: Reducing waste through efficient cutting techniques and recycled packaging.

Lead Times and Scalability

Production timelines vary based on complexity:

Standard Delivery: 25–35 days for simple designs.

Complex Projects: Up to 65 days for multi-material bags or custom hardware.

Peak Season Support: Rush order options for urgent campaigns, backed by a scalable supply chain.

Weierken’s Expertise in OEM Cooler Bag Manufacturing

Weierken stands out as a leader in oem cooler bag production by merging innovation with reliability. Our capabilities include:

End-to-End Solutions: From material sourcing to final shipment, reducing client overhead.

Certification Adherence: ISO 9001, BSCI, and FDA standards for global market access.

Cost-Efficiency: Bulk material procurement lowers unit costs, especially for MOQs as low as 500 pieces.

Case Study: A sports drink brand partnered with Weierken to develop lightweight, leak-proof custom cooler bags for marathon events, resulting in a 30% increase in participant engagement.

Frequently Asked Questions (FAQ)

Q1: What is the typical minimum order quantity (MOQ) for oem cooler bag projects?

A: MOQs start at 500 units for standard designs, but Weierken offers flexible options for smaller batches during trial phases.

Q2: How do you ensure the durability of custom cooler bags in extreme conditions?

A: We conduct rigorous tests, including load-bearing checks for straps and thermal cycling for insulation, using industry-standard equipment.

Q3: Can you source sustainable materials like RPET for eco-friendly campaigns?

A: Yes. Weierken prioritizes GRS-certified RPET and recycled polyester, with documentation provided for compliance verification.

Q4: What certifications does Weierken hold for quality and safety?

A: We are certified under ISO 9001, BSCI, and FDA standards, ensuring products meet international regulatory requirements.

Q5: How do you handle urgent orders during peak seasons?

A: Our streamlined supply chain and reserve production lines enable rush deliveries within 15–20 days for repeat clients.

OEM cooler bag manufacturing is a strategic investment that blends practicality with brand storytelling. By prioritizing R&D, compliance, and scalability, Weierken empowers businesses to deploy high-impact promotional tools that resonate with modern consumers. Whether you’re launching a product or rewarding loyal customers, our oem cooler bag solutions are engineered to exceed expectations. Partner with Weierken to transform your vision into tangible success—contact us today to begin your customization journey.