It’s Friday night. The rush is on. Every order is a race against time and temperature. You’ve perfected your dough, sourced the finest cheese, and your ovens are blazing. But what happens next? The final, fragile leg of the journey—the delivery—is entirely out of your kitchen’s direct control. The thin wall of insulation between your culinary masterpiece and a disappointed customer is the pizza bag. Choosing the supplier for this critical piece isn’t just about buying a container; it’s about selecting a logistics partner for your food’s last mile. A superior pizza bag distributor does more than sell products; they safeguard your brand’s reputation with every delivery. Companies that grasp this, like weierken, focus on engineering this final step, ensuring the pizza that arrives matches the pizza that left.

A cold pizza is more than a complaint; it’s a broken promise. Your bag is the keeper of that promise.

1. Product Quality & Compliance: The Non-Negotiable Foundation

This is where your scrutiny must be fiercest. The bag is an extension of your kitchen.

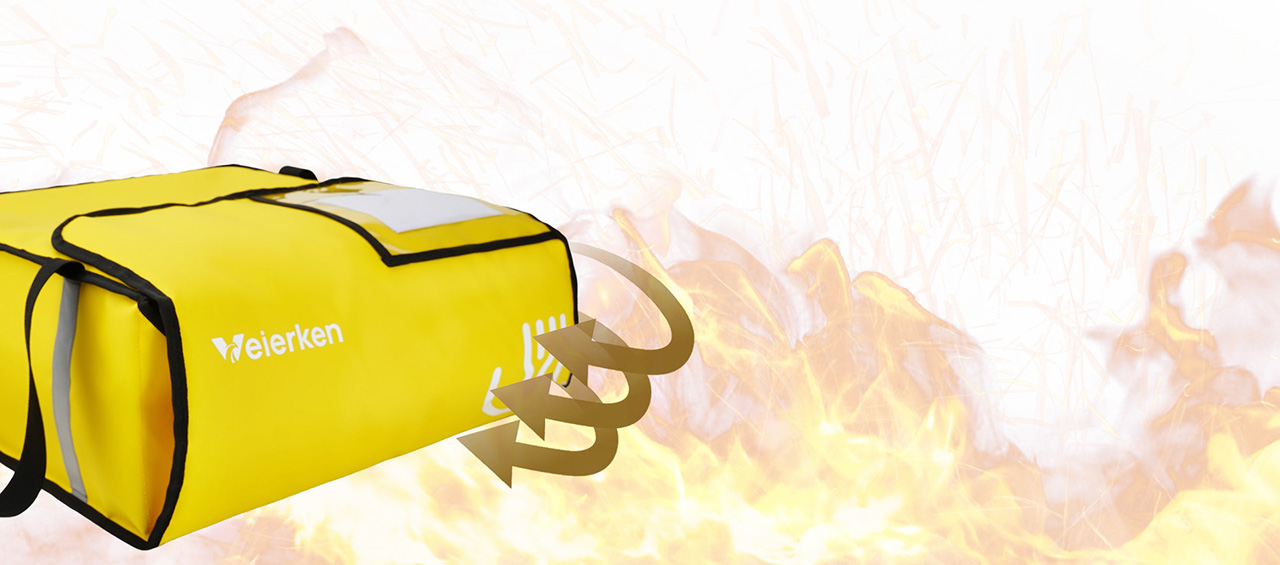

Is Thermal Performance Stable and Reliable?

Consistency is king. A bag that works perfectly one day and fails the next is a liability. You need data-backed assurance. Ask about the insulation material’s heat retention over standard delivery windows—30, 45, 60 minutes. It must maintain safe, serving-hot temperatures consistently, regardless of external weather.

Does It Meet Food-Safe Material Standards?

This is non-negotiable. The interior lining must be certified food-contact safe. It should be free from harmful chemicals like PFAS, lead, or phthalates. Reputable distributors will provide material safety data sheets (MSDS) or compliance certificates without hesitation.

Practical Design: Waterproof, Leak-proof, Easy to Clean?

Spills happen. Sauces leak. A quality bag has a waterproof inner liner that contains messes, protecting drivers’ vehicles. The interior should be made from a wipe-clean or washable material. Seams should be sealed to prevent liquid ingress into the insulation.

Is There a Range of Sizes for Different Products?

Your menu isn’t one-size-fits-all. A good distributor offers a portfolio. From personal pizzas to 18-inch giants, and even compartments for sides like wings, garlic knots, or drinks. Versatility in their catalog shows they understand a real restaurant’s diverse needs.

2. Supply Chain & Delivery Capability: Your Operational Backbone

A great product is useless if it doesn’t arrive when you need it. Your distributor’s logistics must be as robust as their bags.

Stable Supply and Rapid Response Ability?

Can they handle your sudden growth or a large, urgent replacement order? Inquire about their inventory levels and manufacturing lead times. A reliable partner prevents operational halts due to equipment shortage.

Support for Customization (Logo, Size, Design)?

Your delivery bag is a mobile billboard. Look for a distributor offering high-quality logo printing, embroidery, or color customization. True partners, like weierken, often provide design services. Beyond branding, check if they accommodate non-standard size requests for unique menu items.

Regional or National Distribution Network?

Where are their warehouses? A distributor with multiple strategic locations can drastically reduce shipping costs and delivery times for you. This network strength is a sign of their scale and reliability, ensuring you get restocks quickly, whether you have one location or fifty.

3. Cost & Sustainability: Calculating True Value

Look beyond the initial price tag. The cheapest option often becomes the most expensive through frequent replacement.

Is the Price Competitive with Bulk-Order Discounts?

Request transparent pricing tiers. A professional pizza bag distributor will have clear rates for 50, 100, or 500+ units. The goal is finding the sweet spot where quality meets a sensible long-term investment.

Are Materials Eco-Friendly and Durable?

Durability equals sustainability. Are outer fabrics abrasion-resistant? Are zippers and handles robust? Are insulation materials like recycled PET or non-fiberglass alternatives used? A longer-lasting bag means less waste and lower cost-per-delivery over time.

Is There a Recycling or Replacement Policy?

This separates leaders from followers. Some distributors offer programs to take back worn-out bags for proper recycling. Others may have trade-in discounts for upgrades. This policy demonstrates a commitment to a product’s full lifecycle, aligning with modern consumer values.

4. After-Sales Service & Support: The Trust Factor

The relationship shouldn’t end at the point of sale. Ongoing support is critical.

Product Warranty and Post-Purchase Support?

What happens if a seam fails or a zipper breaks within a reasonable timeframe? A clear warranty—even 6 or 12 months—shows faith in product durability. Easy access to a customer service team for parts or advice is essential.

Can They Provide Samples or On-Site Testing?

“Try before you buy” is a powerful offer. Will they send a sample unit for you to test with your actual products? This allows you to verify claimed thermal insulation properties firsthand. It’s a sign of a confident and customer-centric supplier.

Are There Verifiable Success Stories or Case Studies?

Ask for references or examples of similar-sized pizzerias or chains they work with. A proven track record in your industry reduces your risk. Testimonials and case studies provide social proof of their reliability and impact.

5. Industry Fit & Innovation: Thinking Ahead

The best partners don’t just meet today’s needs; they anticipate tomorrow’s challenges.

Do They Understand Pizza-Specific Needs?

It’s not just about heat retention; it’s about pizza retention. Does the bag design prevent crushing? Are handles ergonomic for quick, secure carrying? Do they know the ideal temperature window for melted cheese and a crisp crust? This niche expertise is invaluable.

Are They Tracking Industry Trends?

Ask about their R&D. Are they exploring innovations like phase-change material inserts for longer holds? What about bags with integrated IoT sensors to track temperature in transit? Are they developing new, fully compostable or recycled material lines? A forward-thinking partner, such as weierken, invests in these advancements, giving you a future-ready edge.

Selecting your pizza bag distributor is a strategic decision that directly impacts customer satisfaction, operational smoothness, and your brand’s environmental footprint. It’s a choice between a simple vendor and a true partner in your success. By meticulously working through this checklist—from the foundational quality tests to the forward-looking innovation questions—you empower yourself to make an informed decision. You choose a partner who ensures that the final, crucial step of the delivery journey is as flawless as the first. In this high-stakes environment, aligning with a focused and reliable provider can make all the difference, turning every delivered pizza into a guaranteed delight.

Frequently Asked Questions (FAQs) About Pizza Bag Distributors

Q1: What is the most important factor when choosing a pizza bag distributor?

A1: While all factors are interconnected, product quality and compliance form the absolute bedrock. A bag that fails to keep food safe and hot, or uses non-compliant materials, will undermine every other benefit. Always start your vetting with rigorous checks on thermal performance certification and food-safe material standards.

Q2: How can I verify a distributor’s claims about thermal insulation properties?

A2: First, ask for standardized test data from an independent lab. Second, and most effectively, request physical samples to conduct your own real-world tests. Load them with your pizzas at peak oven temperature, simulate a delivery run, and measure the core temperature upon “arrival.” A trustworthy distributor will encourage this.

Q3: Is customization from a pizza bag distributor worth the potential extra cost and lead time?

A3: Almost always, yes. Customization, especially logo printing, transforms a utility item into a powerful marketing tool. Every delivery becomes brand reinforcement. For unique menu items, custom sizes are essential for product integrity. The investment typically pays for itself in enhanced brand visibility and professional presentation.

Q4: Why should I consider a distributor’s sustainability policies?

A4: Sustainability is a growing concern for consumers and can impact your brand image. Policies around durable, eco-friendly materials and end-of-life recycling demonstrate a shared commitment to reducing waste. Furthermore, highly durable bags have a lower total cost of ownership, saving you money on frequent replacements.

Q5: We are a small, single-location pizzeria. Do large-scale distributors cater to us?

A5: A professional and reputable pizza bag distributor will have scalable solutions. Many offer starter kits or smaller bulk order tiers (e.g., 10-25 bags) designed for growing businesses. Look for distributors that provide the same level of product quality and support regardless of order size, as your needs will evolve.