The outdoor industry is undergoing a fundamental shift. Ten years ago, the primary conversation between a brand and a camping bag distributor revolved almost exclusively around price per unit and colorways. Today, that conversation has moved to the molecular level. Procurement professionals and product managers now scrutinize technical data sheets just as closely as they do shipping manifests.

If you are sourcing gear for a modern outdoor brand, you know that the “fabric” is no longer just cloth. It is a piece of engineering. Your customers—whether they are weekend hikers or alpine expedition leaders—demand gear that is lighter, stronger, and significantly more sustainable. A distributor who relies on outdated material catalogs is a liability to your brand’s growth.

Top-tier suppliers, including industry veterans like weierken, have adapted by integrating advanced material science into their production lines. Identifying a partner who can navigate these material trends is crucial for staying relevant. Here are the five material innovations that a competent camping bag distributor must be able to offer you today.

1. Mature Application of High-Performance Recycled Nylon and Polyester

The era of “greenwashing” is ending. Consumers can tell the difference between a marketing gimmick and genuine sustainability. Consequently, the standard for entry in the outdoor market now involves the use of post-consumer recycled (PCR) materials.

The Shift to GRS-Certified Synthetics

Historically, recycled polyester had a reputation for being weaker or having inconsistent color absorption compared to virgin fiber. That is no longer the case. Advanced chemical recycling processes now allow a camping bag distributor to source regenerated nylon (often from discarded fishing nets) and polyester (from PET bottles) that match the tensile strength and abrasion resistance of virgin materials.

Value for Your Business (B-End)

For a procurement manager, the key lies in certification. A reliable supplier must provide Global Recycled Standard (GRS) certification.

- Regulatory Compliance: The EU and North America are tightening laws around textile waste and circular economy standards. Using verified recycled materials helps you stay compliant.

- ESG Reporting: Large retailers often require environmental data. A distributor who provides clear traceability and carbon footprint data simplifies your ESG reporting.

- Consumer Trust: You can market your bags with specific claims, such as “Made from 100% Ocean-Bound Plastic,” backed by the audit trails your distributor provides.

2. Innovation in Lightweight and High-Strength Composite Fabrics

The Ultralight (UL) hiking movement has graduated from a niche subculture to a mainstream demand. Hikers want to move faster with less fatigue, and they expect their gear to shed ounces without sacrificing durability. This demand has birthed a new class of laminated fabrics.

X-Pac and Dyneema® Composite Fabrics (DCF)

A forward-thinking camping bag distributor will have access to and experience with composite laminates.

- X-Pac: This material uses a multi-layer construction, often featuring a distinct “X-ply” reinforcement grid. It is waterproof by construction, stiffer, and holds its shape better than traditional woven nylon.

- DCF (formerly Cuben Fiber): Known for being weight-for-weight stronger than steel, this is the gold standard for high-end ultralight gear.

Manufacturing Expertise is Key

Sourcing the fabric is only half the battle. These materials behave differently under the needle than standard canvas or nylon. They require specific tension settings, specialized needles, and often, bonded or taped seams rather than traditional stitching to maintain their waterproof integrity.

If your camping bag distributor lacks experience here, you will face high defect rates. However, when done right, these materials allow your brand to enter the high-value “Pro” market segment. You save on R&D costs by leveraging the distributor’s existing manufacturing protocols for these difficult fabrics.

3. Breakthroughs in Bio-Based and Biodegradable Materials

While recycling handles the beginning of the product life cycle, the industry is now looking at the end. What happens when a backpack is finally retired? The cutting edge of material science is moving toward “regeneration” using bio-based polymers.

Beyond Fossil Fuels

Innovative distributors are now experimenting with materials that reduce reliance on petroleum.

- PLA (Polylactic Acid): Derived from fermented plant starch (usually corn), PLA coatings can replace traditional PU coatings for water resistance, offering a lower carbon footprint.

- Bio-based TPU: Thermoplastic Polyurethane is essential for durability, but new versions are being synthesized from castor beans rather than oil.

- Mycelium Composites: While still emerging, fungal-based foams and leathers are being tested for back panels and padding.

Strategic Advantage for Brands

Working with a camping bag distributor who offers small-batch runs of these experimental materials gives you a massive marketing advantage.

- Market Testing: You can launch a “Concept Series” or a limited edition eco-line to test consumer appetite without committing to a massive order.

- Brand Image: It positions your company as a pioneer. Even if these items represent a small percentage of your SKU count, the halo effect on your brand equity is substantial.

4. Integration of Smart and Functional Textiles

A backpack is no longer just a sack to carry things; it is becoming an active interface between the user and the environment. This trend involves integrating textiles that perform a function beyond simple containment.

The Active Microclimate

Manufacturers like weierken have begun exploring how materials can regulate comfort.

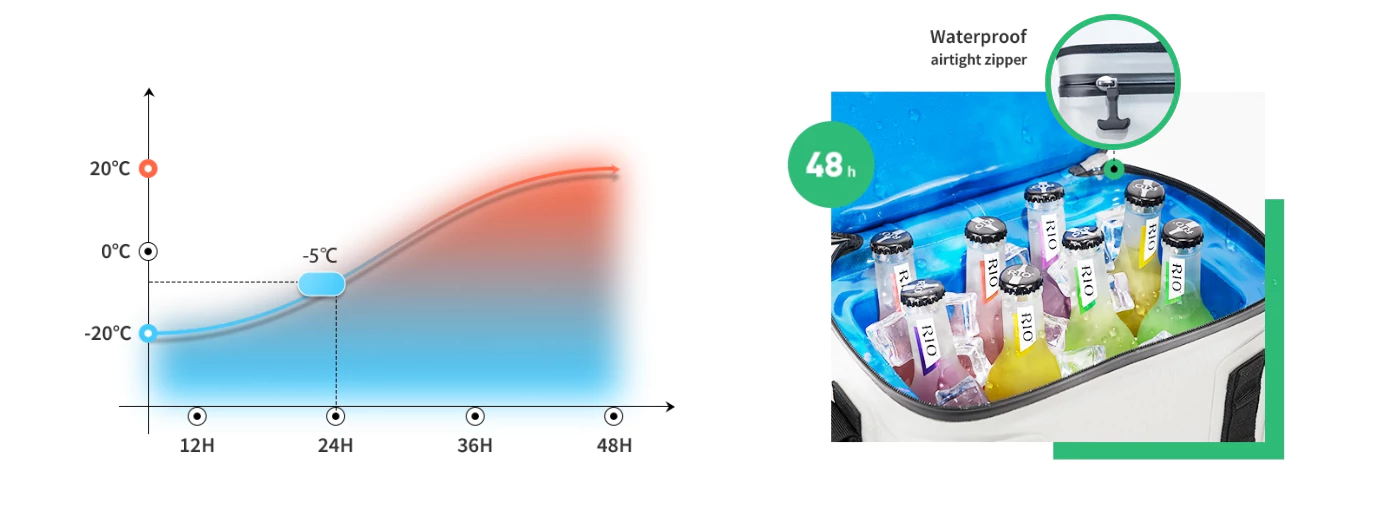

- Phase Change Materials (PCM): These are integrated into the lining or back panel. PCMs absorb and release thermal energy to maintain a constant temperature. This prevents the “sweaty back” syndrome common in hiking by reducing the temperature spikes that cause perspiration.

- PFC-Free DWR: The Durable Water Repellent (DWR) coating is critical for keeping gear dry. The industry is moving rapidly toward non-fluorinated (C0) alternatives that are safer for the environment but require precise application to remain effective.

Tech-Ready Fabrics

We are also seeing the rise of conductive fibers woven directly into the pack. This allows for:

- Integrated Lighting: LED strands woven into the outer shell for cyclist or hiker safety at night.

- Heating Elements: Conductive threads that can provide warmth in alpine conditions, powered by a standard power bank.

For the B-end buyer, this is about increasing the Average Order Value (AOV). A standard hiking bag commands a standard price. A bag that actively manages body temperature or improves safety via integrated tech commands a premium. Your camping bag distributor should have the engineering capability to merge these soft goods with hard tech components seamlessly.

5. The Return to Extreme Durability and Repairability

There is a growing backlash against “fast fashion” in the outdoor world. The “Buy It For Life” philosophy is returning, driven by consumers who want gear that tells a story and lasts for decades.

Heavy-Duty Classics

This trend sees a resurgence of ultra-robust materials like:

- Cordura® Nylon: specifically the higher denier ranges (500D to 1000D).

- Dyneema® Blends: Woven with denim or canvas to create abrasion resistance that is off the charts.

Designing for Repair

A top camping bag distributor does not just sell you a product; they help you build a lifecycle service. This involves specific design choices:

- Modular Components: Designing shoulder straps and hip belts that can be easily unbuckled and replaced if they wear out, rather than sewn in permanently.

- Repair Friendly Coatings: Some modern silicone coatings are impossible to glue. A smart distributor selects fabrics that accept standard repair tapes, allowing users to fix field punctures easily.

Building Brand Loyalty

By offering a product designed to be repaired, you build immense trust. You are telling your customer, “We believe this bag will last so long that you might need to fix it eventually.” Your distributor plays a vital role here by supplying the spare parts and repair kits that you can sell or provide to your customers, creating a secondary revenue stream and a deeper customer relationship.

The role of a camping bag distributor has evolved from a simple logistics provider to a critical technology partner. The materials listed above—recycled synthetics, high-tech composites, bio-based polymers, smart textiles, and ultra-durable weaves—are not just trends. They are the new benchmarks for quality and responsibility in the outdoor industry.

Vetting a supplier now requires looking at their fabric sourcing network as much as their factory floor. Are they pushing the boundaries of what is possible with eco-friendly coatings? Do they have the technical skill to sew complex laminates without compromising water resistance?

Brands like weierken have demonstrated that combining robust manufacturing capabilities with a forward-thinking approach to material science is the recipe for success. By aligning with a distributor who champions these five material trends, you position your brand to meet the demands of the modern adventurer—sustainable, high-performance, and ready for anything.

Frequently Asked Questions (FAQ)

1. How does the cost of GRS-certified recycled nylon compare to virgin nylon?

Currently, high-quality recycled nylon typically carries a premium of 10% to 15% over virgin materials due to the complex collection and reprocessing required. However, as supply chains mature and more camping bag distributors adopt these materials, the price gap is narrowing. The marketing value and compliance benefits often outweigh this initial material cost.

2. Can bio-based materials like PLA really withstand harsh outdoor conditions?

Yes, but with caveats. Early bio-plastics were brittle, but modern formulations used in outdoor gear are reinforced for durability. However, they are generally best suited for less abrasive areas of a pack or for gear intended for moderate use. A knowledgeable distributor will advise on the correct placement of bio-materials to balance sustainability with performance.

3. What is the main manufacturing challenge with Ultra-High-Molecular-Weight Polyethylene (UHMWPE) fabrics?

Fabrics like Dyneema are incredibly slippery and have very low stretch. This makes them difficult to cut and sew precisely without puckering. A standard factory often struggles with this. You need a camping bag distributor with specific tooling and experienced technicians who understand how to handle low-friction, high-cost composite fabrics.

4. Are PFC-free DWR coatings as effective as traditional C8 treatments?

PFC-free (C0) coatings have improved drastically. While they match the initial water repellency of older toxic C8 chemistries, they generally require more frequent cleaning and re-treatment to maintain that performance. Your distributor should provide care instructions that you can pass on to your customers to ensure longevity.

5. What is the minimum order quantity (MOQ) for custom fabrics like X-Pac?

Branded technical fabrics often have higher MOQs from the mill. While a distributor might offer standard nylon at 500 units, a custom color or specific laminate weight in X-Pac might require an order of 1,000+ units or a commitment to consume a specific yardage of fabric. It is vital to discuss these material-specific thresholds early in the negotiation.

Ready to upgrade your product line with next-generation materials?

[Inquire Now] to discuss your technical specifications and request material samples.