When your business requires a reliable supply of floatable bag bulk order shipments, understanding the intricacies of the cost structure is paramount. A bulk order of floatable bags isn’t just a simple commodity purchase; it’s a strategic procurement decision that impacts your logistics, branding, and bottom line. Many buyers focus solely on the per-unit price, but the true cost is shaped by a confluence of factors from material selection to final delivery.

Companies like Weierken, with extensive experience in manufacturing and supplying these essential packaging items, understand that a transparent breakdown of costs empowers buyers to make smarter, more economical decisions. This analysis dives into the five key drivers that determine your final investment in a floatable bag bulk order, providing a roadmap for optimizing your procurement strategy.

Material Cost and Type: The Foundation of Floatation and Price

The primary function of a floatable bag is to provide buoyancy and protection, and the materials used are the most significant cost component. Not all foam is created equal, and the choice directly influences performance, durability, and price.

- EPE (Expanded Polyethylene): This is a popular choice for floatable bag bulk order procurements due to its excellent water resistance, durability, and cost-effectiveness. EPE is resilient, non-toxic, and offers good buoyancy. It’s often the go-to material for standard applications, providing a solid balance between performance and price. For businesses looking for a reliable, all-purpose solution, EPE is frequently the most economical option in large quantities.

- EVA (Ethylene-Vinyl Acetate): EVA foam is known for its superior flexibility, soft texture, and smooth finish. It has a higher density and is often more durable than EPE, but this comes at a premium. EVA is commonly used for higher-end products or items that require a more premium feel. Its closed-cell structure also makes it highly water-resistant. When placing a large quantity floatable bag order with EVA, expect a higher base material cost.

- Other Foams (IXPE, PE): Cross-linked polyethylenes (IXPE) offer enhanced strength and heat resistance, while other PE foams might be used for specific compression requirements. Each variant has a distinct cost profile.

Supplier Strategy: For a floatable bag bulk order, partnering directly with a manufacturer that controls its material sourcing, like Weierken, can lead to significant savings. They can often procure raw foam in massive volumes, passing the stability of cost and supply onto you. Inquiring about the material’s density (e.g., 20kg/m³, 25kg/m³) is also crucial, as higher density typically means better protection and a higher price.

Order Volume and Pricing Tiers: The Economics of Scale

This is the most straightforward yet critical factor. The unit price for a floatable bag bulk order is not fixed; it decreases as the order quantity increases. Manufacturers have established pricing tiers to reflect the reduced per-unit cost of setup, labor, and material handling for larger runs.

- Sample/Small Batch (e.g., 100-500 pcs): This range carries the highest per-unit cost. Setup costs for machines and any custom dies are amortized over a small number of units.

- Medium Bulk Order (e.g., 1,000-10,000 pcs): This is where significant per-unit cost reductions begin. The initial setup costs are spread across more units, making the price more attractive.

- Large Volume Order (e.g., 50,000+ pcs): This tier offers the most competitive pricing. At this scale, production lines can run optimally, material waste is minimized, and the manufacturer can offer their best rates. This is the ideal scenario for businesses with predictable, high-volume needs.

To optimize cost, consolidate your demand. Instead of placing multiple small orders throughout the year, forecast your annual requirement and place a single, larger floatable bag bulk order. This approach not only secures a lower price but also ensures consistency in product quality and reduces administrative overhead.

Customization and Process Complexity: Adding Value and Cost

Standard, off-the-shelf floatable bags are the most cost-effective. However, most businesses require some level of customization to meet their specific needs, and each addition introduces complexity and cost.

- Custom Printing & Branding: Adding your company logo, handling instructions, or marketing messages is a common request. The cost depends on the number of colors, the print area size, and the printing technology used (e.g., silk-screen printing vs. flexographic printing). A simple one-color logo is relatively inexpensive, while a full-color, complex graphic will add more to the final custom floatable bag bulk order price.

- Size and Shape Adjustments: If the standard sizes don’t fit your product, creating a new size requires tooling and die-cutting charges. This is a one-time or semi-permanent cost that is factored into the unit price. The more complex the shape, the higher the tooling cost.

- Structural Design: Features like reinforced handles, zip locks, or multi-layer laminations for extra barrier protection add significant steps to the manufacturing process. While these features enhance functionality, they also increase labor, material usage, and machine time.

A manufacturer that offers comprehensive services, such as Weierken, can provide a clear cost-benefit analysis for your customization ideas, helping you decide which features are essential and which can be modified to keep your floatable bag bulk order within budget.

Logistics and Transportation Costs: The B2B Supply Chain Reality

For a floatable bag bulk order, the cost does not end at the factory gate. Floatable bags are lightweight but incredibly bulky. Their low density means they take up a lot of space in shipping containers compared to their actual weight—a concept known as “volumetric weight” or “dim weight.” This characteristic makes logistics a major cost driver.

- Volumetric Weight: Freight carriers charge based on whichever is greater: the actual weight or the volumetric weight. Since a pallet of floatable bags is light but fills a container, you will almost always be charged based on the space it consumes. Efficient packaging and compression of the bags before shipping can marginally reduce this volume.

- Shipping Method: The choice between sea freight, air freight, and land transport has a massive impact. Sea freight is the most economical for international floatable bag bulk orders but has the longest lead time. Air freight is fast but prohibitively expensive for such low-density items. Your manufacturer should be able to advise on the most cost-effective and reliable shipping method based on your destination and timeline.

- Destination and Port Charges: Final delivery location, import duties, and port handling fees are all part of the total landed cost. A reliable supplier will have experience navigating international logistics and can provide accurate shipping quotes as part of your overall floatable bag bulk order proposal.

Market Dynamics and Supplier Selection: Building a Strategic Partnership

The broader market environment and your choice of supplier are overarching factors that influence all others. The laws of supply and demand for raw polymers, global economic conditions, and even seasonal trends can cause material prices to fluctuate.

- Assessing Market Conditions: A period of high demand or constrained raw material supply can lead to price increases across the board. A knowledgeable partner can provide insights into market trends, helping you time your floatable bag bulk order to secure better rates.

- Supplier Selection Criteria: Price should not be the sole criterion. Key factors for selecting a supplier for your floatable bag bulk order include:

- Manufacturing Capability: Do they produce in-house, or are they a middleman?

- Quality Control: What certifications do they hold (e.g., ISO, BSCI)? Can they provide material safety data sheets?

- Communication and Reliability: Are they responsive and transparent about production progress and potential delays?

- Financial Stability: Can they handle a large order without cash flow issues?

- Long-Term Partnership and Negotiation: Building a relationship with a single, capable manufacturer like Weierken yields long-term benefits. As a repeat customer, you gain negotiation power, priority production slots, and a partner invested in your success. They are more likely to provide favorable pricing tiers, collaborate on value engineering, and ensure consistent quality for every subsequent floatable bag bulk order.

A strategic approach to your next floatable bag bulk order requires looking beyond the sticker price. By thoroughly evaluating material options, leveraging volume for better pricing, carefully considering customization needs, planning for logistics, and choosing a supplier that acts as a true partner, you can significantly optimize your total expenditure. It’s a complex procurement puzzle where each piece—from the type of foam to the final shipping container—matters. As you plan your procurement, consider engaging with technical experts who can guide you through these decisions, much like the team at Weierken does for its clients, ensuring that your investment in floatable bags is both cost-effective and perfectly tailored to your requirements.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for a large floatable bag bulk order?

A1: Lead times can vary significantly based on order size, customization, and the manufacturer’s current production schedule. For a standard large quantity floatable bag order with minimal customization, expect a lead time of 15-30 days after order confirmation. Complex customizations or peak season demand can extend this timeline. It’s always best to request a detailed production schedule from your supplier.

Q2: Can I get a sample before placing a full bulk order?

A2: Yes, most reputable manufacturers, including Weierken, encourage potential clients to evaluate samples. This allows you to verify the material quality, workmanship, and suitability for your product. There is usually a nominal fee for custom-made samples, which is often deductible from your final floatable bag bulk order invoice.

Q3: How are floatable bags packaged for international shipping to minimize logistics costs?

A3: To combat their high volume, manufacturers use heavy-duty compression packing. The bags are tightly compressed and vacuum-sealed into compact bales, which are then packed into cartons and onto pallets. This process dramatically reduces the volumetric weight, making sea freight for your international floatable bag bulk order much more economical.

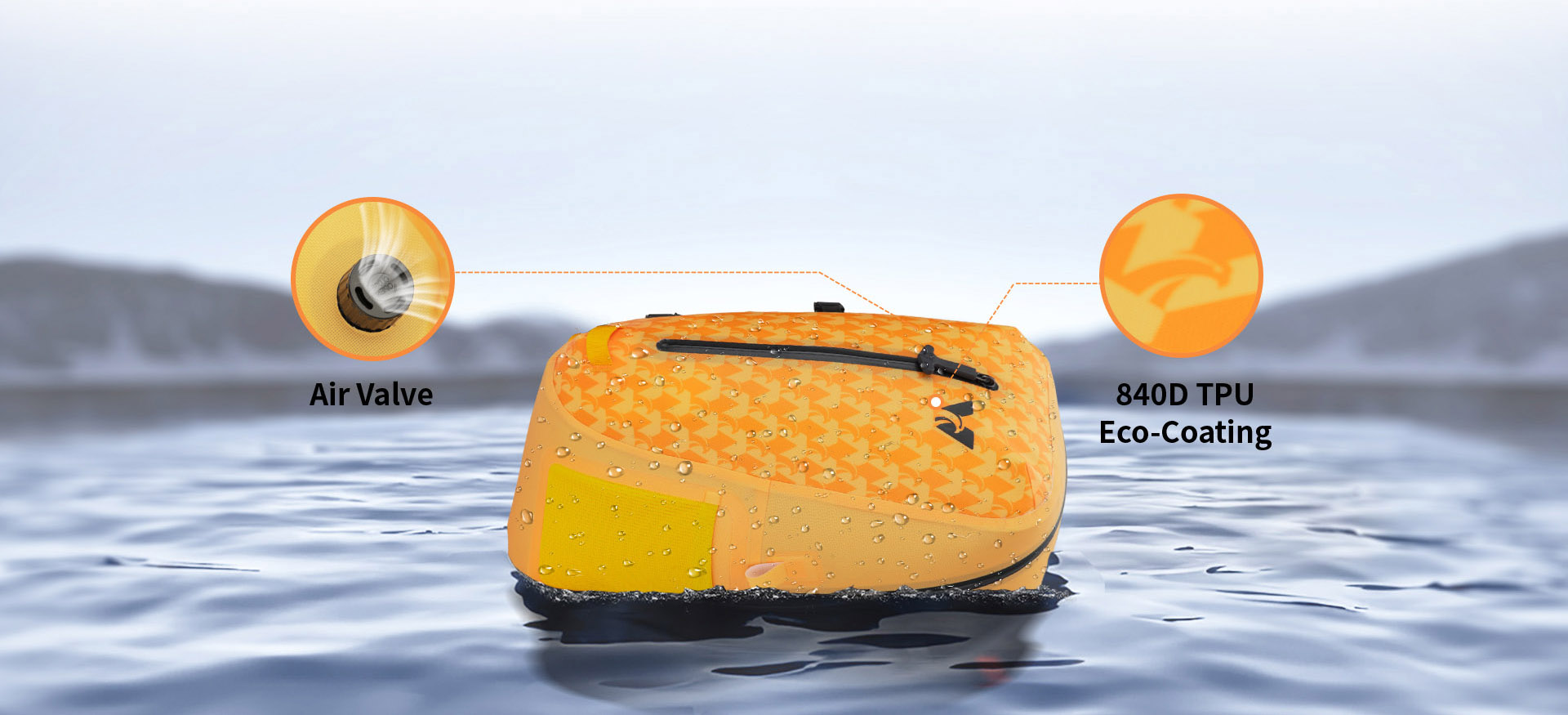

Q4: Are there any eco-friendly material options available for floatable bags?

A4: Absolutely. The industry is evolving, and options are available. Some manufacturers offer foams that are recyclable or made with a percentage of recycled content. While these eco-friendly alternatives may come at a slightly higher cost, they are an important consideration for brands focused on sustainability for their floatable bag bulk order. Be sure to discuss this requirement explicitly with your supplier.

Q5: What information do I need to provide to get an accurate quotation for a custom floatable bag bulk order?

A5: To receive a precise and comparable quote, you should provide the following details:

- Required Quantity: Your estimated annual volume or specific order quantity.

- Desired Dimensions: Length, width, and thickness.

- Material Specification: Preferred foam type (e.g., EPE, EVA) and density.

- Customization Details: Artwork for printing, required handle types, or any special structural features.

- Destination Port: For shipping cost calculation.