In commercial and industrial sectors where moisture protection is non-negotiable, selecting the right waterproof bag manufacturers represents a crucial procurement decision that impacts operational efficiency, product integrity, and bottom-line results. For procurement specialists, supply chain managers, and brand owners across multiple industries, the choice of manufacturing partner determines not only product quality but also supply chain reliability and brand protection.

This comprehensive guide provides a detailed framework for evaluating waterproof bag manufacturers based on technical capabilities, industry-specific requirements, and commercial considerations that matter in B2B relationships. We examine key selection criteria that separate exceptional manufacturers from average suppliers, ensuring your investment delivers optimal value and performance.

Understanding Waterproofing Technologies: Materials, Methods, and Standards

Material Selection: Comparative Analysis

The foundation of any effective waterproof bag lies in its material composition. Different applications demand different material solutions:

TPU (Thermoplastic Polyurethane): Offers excellent clarity, flexibility, and durability with high abrasion resistance. Ideal for applications requiring visual content inspection while maintaining protection. TPU is increasingly preferred for its environmental profile compared to PVC.

PVC (Polyvinyl Chloride): Provides cost-effective waterproofing with good durability but has faced environmental scrutiny due to chlorine content and plasticizer migration issues. Still used in industrial applications where cost is primary concern.

Coated Nylons (PU Coating): Offer an excellent strength-to-weight ratio, making them ideal for lightweight waterproof bag applications where reducing carrier fatigue is important. Typically feature urethane coatings on high-denier nylon fabrics for durable waterproof protection.

Laminated Fabrics: Incorporate multiple layers including waterproof membranes (e.g., TPU film) bonded to outer fabrics, creating highly reliable barriers against moisture penetration.

Manufacturing Processes and Waterproof Integrity

The manufacturing process significantly impacts the ultimate waterproof performance:

RF (Radio Frequency) Welding: Uses high-frequency electromagnetic energy to create molecular bonds between thermoplastic materials, producing seams that are as waterproof as the base material itself. This method creates the most reliable waterproof seals.

Heat Sealing/Thermal Welding: Applies controlled heat and pressure to melt and bond materials together. Effective for many applications but requires precise parameter control.

Sewn and Seam Taped: Traditional sewing followed by application of waterproof tape over stitch lines. While cost-effective, this method creates potential failure points at needle penetration sites.

Waterproof Ratings and Testing Standards

Understanding waterproof ratings is essential for specifying appropriate protection levels:

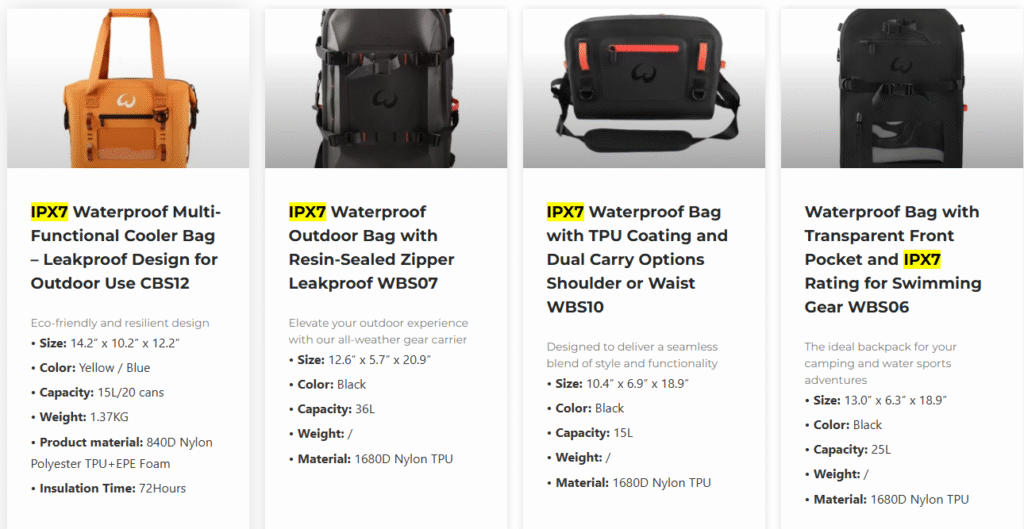

IPX Ratings: The IP (Ingress Protection) rating system classifies protection levels against liquids

IPX-4: Protection against water splashes from all directions

IPX-6: Protection against powerful water jets

IPX-7: Protection against immersion in water up to 1 meter for 30 minutes

IPX-8: Protection against continuous immersion under specified conditions

Hydrostatic Head Testing: Measures water resistance in millimeters (e.g., 1000mm, 5000mm, 10,000mm) indicating the water pressure a fabric can withstand before leaking. Higher numbers indicate better protection.

Industry-Specific Testing: Including spray tests, immersion tests, and real-world condition simulations that replicate actual use environments.

Industry-Specific Applications and Technical Requirements

Food Service and Delivery Applications

The food industry presents unique challenges for waterproof bag solutions, requiring both moisture protection and food safety compliance:

Restaurant Waterproof Bag Solutions: For take out operations, these bags must prevent leakage while maintaining food quality. Key requirements include leakproof construction, easy-to-clean interiors, and compliance with food safety regulations.

Food Courier Waterproof Bag: Designed for last-mile delivery, these solutions require durable waterproof bag construction that withstands daily use while protecting contents from weather conditions during transport.

Pizza Waterproof Bag: Specialized design requirements include heat retention properties alongside waterproofing, often requiring thermal-control waterproof bag capabilities with large-capacity dimensions to accommodate various pizza sizes.

Catering Waterproof Bag: For large-scale food transport, these solutions need multi-zone waterproof bag configurations with compartmentalization for different meal components while maintaining complete waterproof integrity.

Cold Chain and Perishable Goods Transport

Maintaining temperature integrity while preventing moisture damage is critical for perishable goods:

Seafood Waterproof Bag: Requires robust waterproofing to contain melting ice and prevent cross-contamination, often needing reusable waterproof bag solutions that withstand harsh marine environments.

Frozen Food Waterproof Bag: Must maintain waterproof integrity at low temperatures where materials can become brittle, requiring specialized material formulations.

Ice-Cream Waterproof Bag: Combines thermal-control capabilities with absolute waterproofing to prevent both melting and moisture damage during transport.

Dairy Waterproof Bag: Protects sensitive dairy products from both moisture and temperature fluctuations during cold shipping operations.

Grocery and Retail Applications

The retail sector demands both functional performance and aesthetic appeal:

Grocery Waterproof Bag: Reusable solutions for customers that provide reliable protection against rain and spills while offering branding opportunities.

Fresh Food Waterproof Bag: Designed for produce transport that may require breathability while still protecting against external moisture.

Salad Waterproof Bag: Specialized packaging that maintains crispness while preventing condensation damage.

Specialized Applications

Fresh Meat Waterproof Bag: Requires leakproof construction capable of containing liquids from raw meat products while preventing external contamination.

Frozen Meat Waterproof Bag: Combines waterproofing with insulation for extended transport times.

Cheese Waterproof Bag: Protects against moisture while allowing appropriate breathability for cheese maturation during transport.

Cake Waterproof Bag: Often requires transparent sections for product visibility while ensuring complete protection against moisture damage.

Critical Procurement Factors for Waterproof Bag Manufacturers

Technical Capabilities and Customization Expertise

Evaluating a manufacturer’s technical capabilities requires assessing multiple dimensions:

Design and Engineering Support: Look for manufacturers offering comprehensive design services including CAD capabilities, material selection guidance, and functional design optimization.

Prototyping and Sampling Process: A robust prototyping process allows for design validation and performance testing before full-scale production. Expect multiple iteration cycles for complex custom designs.

OEM/ODM Services: Determine whether the manufacturer can work with your designs (OEM) or provide complete design and manufacturing services (ODM). Each approach has different implications for IP protection and development timelines.

Material Selection and Sustainability Compliance

Environmental considerations increasingly influence procurement decisions:

Recycled Materials: Inquire about availability of RPET (recycled polyethylene terephthalate) and other recycled content materials that meet performance requirements.

Environmental Certifications: Require certifications including:

GRS (Global Recycled Standard): Verifies recycled content claims

REACH Compliance: Ensures chemical safety and restrictions compliance

FDA Compliance: Essential for food-contact applications

End-of-Life Considerations: Progressive manufacturers offer solutions for recyclability and circular economy integration.

Quality Assurance and Certification Compliance

Quality management systems provide assurance of consistent manufacturing quality:

ISO 9001 Certification: Demonstrates adherence to quality management principles and continuous improvement processes.

BSCI Certification: Indicates social compliance and ethical manufacturing practices.

Product Testing Protocols: Require details on in-process quality checks, final inspection procedures, and third-party testing validation.

Production Capacity and Supply Chain Reliability

Manufacturing capabilities must align with your volume requirements and timeline constraints:

Production Scalability: Assess whether the manufacturer can handle both initial order volumes and future growth requirements without quality degradation.

Peak Season Capacity: Evaluate their ability to accommodate urgent replenishment orders during high-demand periods.

Lead Time Management: Transparent production timelines typically range from 25-65 days depending on order complexity, customization level, and seasonal factors. Reliable manufacturers provide accurate lead time estimates and adhere to committed schedules.

Performance Testing and Validation Protocols

Reputable manufacturers employ rigorous testing methodologies:

Laboratory Testing: Standardized tests including hydrostatic pressure testing, spray ratings, and accelerated aging tests.

Field Testing: Real-world testing under actual use conditions to validate laboratory results.

Custom Testing Protocols: Ability to develop application-specific testing that matches your unique use case requirements.

Cost Considerations and Value Analysis

While initial cost matters, total cost of ownership provides a more accurate assessment:

Durability and Lifespan: Higher-quality durable waterproof bag solutions may have higher initial costs but deliver lower cost-per-use through extended service life.

Warranty and Support: Comprehensive warranty terms indicate manufacturer confidence in their products.

Logistics Efficiency: Designs that optimize storage and transport space can reduce secondary costs.

The Manufacturer Evaluation Process: A Step-by-Step Approach

Phase 1: Initial Qualification

Assess technical capabilities against your specific requirements

Verify certifications and compliance documentation

Review manufacturing facilities and quality control processes

Phase 2: Capability Validation

Request and evaluate samples for performance testing

Review prototyping processes and design collaboration capabilities

Assess communication responsiveness and project management approach

Phase 3: Commercial Assessment

Analyze cost structures and value propositions

Evaluate supply chain resilience and risk management practices

Review references and case studies from similar applications

Phase 4: Partnership Development

Establish clear communication protocols and escalation paths

Develop mutually beneficial contract terms

Implement performance metrics and review processes

Future Trends in Waterproof Bag Manufacturing

Staying ahead of industry developments ensures long-term procurement success:

Smart Integration: Increasing incorporation of IoT devices for tracking and condition monitoring

Advanced Materials: Development of more sustainable waterproof materials without performance compromise

Customization Technologies: Digital printing advancements enabling smaller batch customization

Circular Economy Initiatives: Take-back programs and recycling advancements for end-of-life management

Frequently Asked Questions(FAQ)

1. Q: What is the fundamental difference between “water-resistant” and “waterproof” in bag manufacturing, and how is it tested?

A: waterproof bags can repel light moisture (like splashes) for a short time but will eventually allow water to penetrate under pressure or prolonged exposure. Waterproof bags are designed to prevent water ingress entirely, even during immersion. This is validated through standardized tests like the IPX rating system (e.g., IPX-7 for immersion up to 1 meter for 30 minutes) and hydrostatic head testing (measuring the water column pressure, in mm, the fabric can withstand before leaking).

2. Q: For food delivery applications, what material is recommended to balance waterproofing, durability, and food safety?

A: TPU (Thermoplastic Polyurethane) is often the optimal choice. It offers excellent waterproof integrity through RF welding, high durability and abrasion resistance, and is generally considered food-safe and compliant with relevant FDA standards. It also avoids the environmental concerns associated with PVC.

3. Q: How does RF (Radio Frequency) welding create a superior seal compared to sewn and taped seams?

A: RF welding fuses the materials together at a molecular level, creating a seam that is homogenous and as waterproof as the base material itself. In contrast, sewn seams create thousands of needle holes that are potential leak paths. While taping covers these holes, it introduces an adhesive that can degrade over time and creates a potential point of failure, making RF welding the more reliable and durable sealing method.

4. Q: What certifications should we prioritize when sourcing waterproof bags for the European and North American markets?

A: For both markets, REACH compliance is crucial for chemical safety. For food-contact applications, FDA compliance (or its EU equivalents) is non-negotiable. For social responsibility, a BSCI audit report is key. From a quality management perspective, ISO 9001 certification indicates a reliable manufacturing system. If using recycled materials, GRS (Global Recycled Standard) certification verifies the recycled content.

5. Q: What is a realistic timeline for developing and producing a new, fully custom waterproof bag?

A: The timeline has two phases. The development and sampling phase typically takes 2-4 weeks, involving design, material selection, and 1-2 rounds of prototyping. Once the final sample is approved, production for a custom order generally takes 25-65 days, depending on order complexity and volume. A reputable manufacturer will provide a detailed project timeline after understanding your specific requirements.

Selecting the Right Manufacturing Partner

Choosing among waterproof bag manufacturers requires careful evaluation of both technical capabilities and business compatibility. The ideal partner should offer comprehensive services from concept to delivery, maintain stringent quality standards, and demonstrate expertise in your specific industry segment.

Weierken meets these criteria with extensive experience in manufacturing custom waterproof solutions across multiple industries. Our capabilities include:

Advanced waterproofing technologies including RF welding and laminated fabrics

Comprehensive material selection guidance including sustainable options

Certifications including ISO 9001, BSCI, FDA, REACH, and GRS compliance

Reliable production capacity with 25-65 day lead times

Industry-specific expertise in food service, cold chain, and retail applications

Rigorous testing protocols including IP rating validation and hydrostatic testing

Contact Weierken today to discuss your custom waterproof bag requirements, request samples, and receive a detailed quotation tailored to your specific application needs. Our technical team stands ready to help you navigate the complex landscape of waterproofing solutions to identify the optimal approach for your business requirements.