Let’s cut right to the chase. Your next major operational headache, or your most seamless strategic advantage, could very well be your Sailing Bag Distributor. For brand managers, procurement heads at marine retailers, or organizers of the next big regatta, this isn’t a simple vendor transaction. It’s a partnership that directly impacts your cash flow, customer satisfaction, and brand reputation.

A great distributor is an extension of your team. A mediocre one becomes a constant source of firefighting.

The entire evaluation boils down to two non-negotiable pillars: Supply Chain Reliability and Global Logistics Prowess. Fail in either, and you’re left with promises instead of products on your shelf.

Forget glossy brochures. We’re going practical. Here are the six questions you need answered before signing any agreement. This is the due diligence checklist I wish I had years ago.

The 6-Point Interrogation: What to Ask Your Potential Distributor

1. “Can You Map Your Real Coverage and Clientele for Me?”

A distributor’s “global reach” often sounds better on paper. You need the gritty details.

Ask for a client list breakdown. What percentage are marine retailers versus corporate gift buyers? A distributor focused on premium boutiques might struggle with the volume needs of a large sporting goods chain.

Probe their regional depth. Do they just ship to a country, or do they have a local agent, warehouse, or established logistics partner there? Hands-on knowledge of customs in Southern Europe versus the Nordics is invaluable.

Industry focus matters. A general luggage distributor might not grasp why a sailing bag needs specific drain holes, UV-resistant coating, or attachment points for safety lines. You want a partner who speaks the language of the sea.

2. “How Do You Guarantee Supply Stability When Things Get Rough?”

Anyone can move stock in calm seas. Your distributor is tested when the supply chain storms hit.

Dig into their manufacturer relationships. Are they a casual buyer or a strategic partner with certain factories? The latter often gets priority during material shortages.

Get crystal clear on MOQs (Minimum Order Quantities), lead times, and their buffer stock policy for popular items. What’s their standard delivery cycle from order to their warehouse? 30 days? 90 days?

Crucially, ask for a specific example of a recent supply chain disruption they navigated. What was their contingency plan? Did they have alternative manufacturing or raw material sources? Their answer reveals more than any contract clause.

3. “Does Your Product Portfolio Align and Augment My Strategy?”

This is about synergy. A distributor’s brand portfolio can make or break your market positioning.

If you’re a retailer, carrying a sailing bag distributor‘s range that includes both premium and value brands can cater to a wider audience. If you’re a brand, you need to ensure your products aren’t buried or directly undercut by competing brands in their lineup.

Exclusive distribution rights in your territory are a massive advantage. Ask: Do you hold exclusives for any key brands? How quickly do you synchronize with brand launches—are you first to market or months behind?

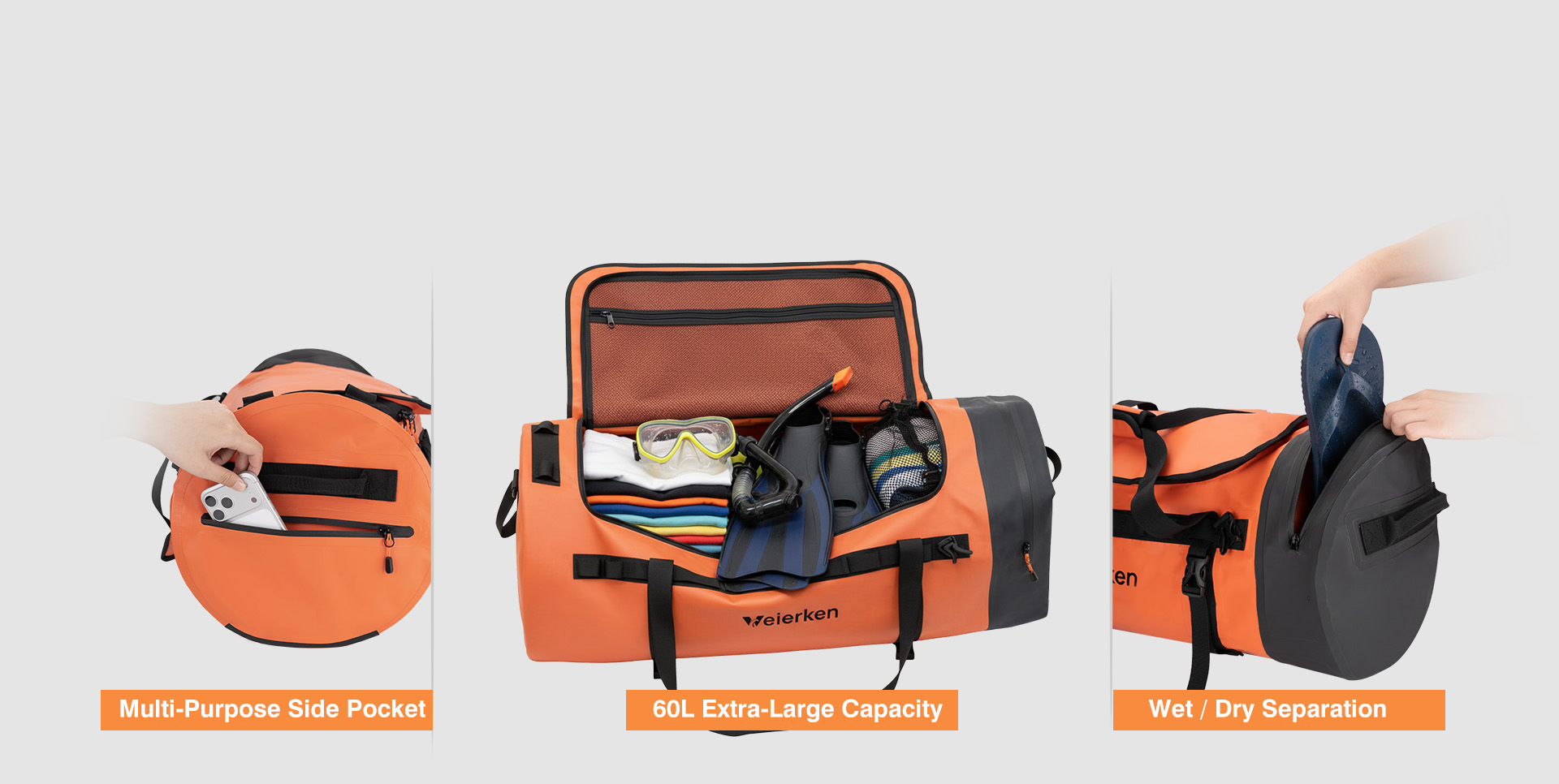

A diverse but focused portfolio, like one that might include durable options from a brand like Weierken alongside more specialized racing gear, shows market understanding.

4. “Walk Me Through Your Logistics: From Your Warehouse to My Customer’s Door.”

This is where margins can evaporate. Global logistics isn’t just about shipping; it’s about visibility and efficiency.

Who are their freight partners? Do they have negotiated rates and reliable lanes on major and secondary routes? Where are their warehouses? Strategic locations can drastically cut down delivery times and import taxes for you.

Ask about order processing time. Is it 24 hours or 5 days? Do they offer real-time inventory visibility through a portal or regular reports?

Most importantly, clarify the “last mile” and Incoterms. Are they delivering to your port (FOB), your warehouse (DDP), or directly to your end customers? Who handles customs clearance? Ambiguity here leads to surprise costs and delays.

5. “Beyond the Unit Price, What’s the Full Financial Picture?”

The cheapest unit price can be the most expensive partnership. Transparency is key.

Request a complete, line-itemed pro forma invoice. It should detail the product cost, shipping, insurance, and any handling fees. Are there hidden charges for small orders or specific packaging?

Understand their payment terms. Net 30? 50% deposit? This affects your cash flow. What is their return policy for defective goods? Who bears the cost of return shipping?

Do they offer incentives for forecasted volume or long-term contracts? A good distributor invests in growing partners, not just making one-off sales.

6. “What Support Do You Provide After the Sale?”

A box-mover is replaceable. A true partner adds value beyond the transaction.

Do they provide high-resolution images, product videos, or spec sheets for your website and sales team? Will their sales rep join you for key account meetings?

Is product training available? Can your staff understand the difference between 600D and 1680D polyester because they explained it?

For corporate clients, what customization capabilities exist—logos, color variations, kit packaging? Do they hold relevant sustainability or safety certifications that are increasingly important for B2B tenders?

A distributor that acts as your local commercial arm, like some comprehensive Weierken partners aim to do, is a strategic asset.

Partner for the Long Voyage

Choosing a Sailing Bag Distributor is a strategic decision with long-term ripple effects. By systematically demanding answers to these six questions, you move from a sales conversation to a partnership evaluation.

You’re not just buying bags; you’re investing in reliability, market intelligence, and logistical peace of mind. You’re selecting a channel that can amplify your brand or ensure your event’s merchandise arrives on time.

Look for the distributor who answers these questions with confidence, detail, and a clear understanding of your business pressures. That’s the partner who won’t just take your order but will help you grow your reach. That’s the value a true specialist, committed to the marine industry, brings to the table.

Frequently Asked Questions (FAQs) on Sailing Bag Distributors

Q1: What is the main difference between a sailing bag manufacturer and a sailing bag distributor?

A1: A manufacturer produces the physical bags. A Distributor purchases bags in bulk from manufacturers (or brand owners) and resells them to retailers, corporations, or event organizers. The distributor‘s core value lies in logistics, inventory holding, regional marketing, and providing local sales/support, saving you from direct import complexities.

Q2: Why shouldn’t I just import sailing bags directly from the manufacturer to save cost?

A2: Direct import can be beneficial for very large, consistent volumes. However, a reputable Sailing Bag Distributor eliminates massive overheads for you: they handle international freight, customs clearance, warehousing, and manage inventory risk. They also provide smaller, more frequent order quantities, freeing up your capital and reducing your logistical burden.

Q3: How important is it for a distributor to have exclusive rights to a brand in my region?

A3: It’s highly important for market control. If you secure a distribution agreement with an exclusive distributor, you prevent price undercutting from other local sources and often get better marketing support. It ensures you are the sole channel for that brand in your territory, protecting your investment in marketing and sales efforts.

Q4: What logistics terms should I look for from a distributor for a smooth process?

A4: Prioritize distributors offering clear Incoterms like DAP (Delivered at Place) or DDP (Delivered Duty Paid) to your warehouse. This means they handle most of the international logistics and costs. Also, seek partners with strong last-mile delivery networks within your country and transparent tracking systems for full shipment visibility.

Q5: Can a sailing bag distributor typically handle custom orders or branding?

A5: Many can, but capabilities vary. A full-service distributor will have strong ties with manufacturers to facilitate customization, such as adding logos, custom colorways, or tailored packaging kits. Always ask for their minimum order quantity (MOQ) for custom work, lead times, and provide them with clear artwork specifications upfront.