Imagine you’re on a trail, a sudden downpour soaks everything in sight. Yet, inside your backpack, your gear remains perfectly dry and secure. That peace of mind isn’t accidental; it’s the result of intentional design and superior craftsmanship. For businesses and organizations looking to create their own branded backpacks, understanding the essential features that make a backpack truly waterproof and functional is critical. Whether you’re partnering with a waterproof bag factory or evaluating different waterproof backpack manufacturers, the details define the final product.

This guide breaks down the 3 non-negotiable features your custom waterproof backpack must have. We’ll explore why each element matters, how it enhances user experience, and what you should discuss with your manufacturing partner. A brand like weierken, for instance, integrates many of these features to ensure their packs meet rigorous demands. Let’s dive into the checklist that will set your custom pack apart.

1. Fully Waterproof Materials (e.g., TPU-Coated Nylon)

The first line of defense against moisture is the fabric itself. Standard backpacks often use water-resistant materials that can only handle a light drizzle. A truly waterproof backpack requires a fully impermeable material.

Function: Materials like TPU (Thermoplastic Polyurethane) laminated to nylon or polyester create a seamless, non-porous barrier. The fabric is technically submersible, preventing water molecules from penetrating under hydrostatic pressure. This is different from a DWR (Durable Water Repellent) coating, which merely causes water to bead up and roll off the surface for a short period.

Value: This ensures that the contents of the backpack stay dry even during heavy rain, accidental submersion in a river, or while on a boat. For a hiking bag OEM project, this is the foundational feature that defines the product’s core promise. When you work with a specialist waterproof backpack manufacturer, they will guide you on the denier (fabric thickness) and coating weight suitable for your target audience’s needs.

2. Fully Taped Seams

If the fabric is waterproof but the stitches aren’t, water will find a way in. Every needle hole from sewing is a potential entry point for water.

Function: Seam taping involves applying a waterproof, heat-activated tape over the inside of every sewn seam. This process seals the thousands of tiny holes created during construction. It’s a meticulous process that requires specialized equipment and skill.

Value: Taped seams are what elevate a water-resistant bag to a genuinely waterproof one. Without them, the backpack has a critical vulnerability. High-end manufacturers, including weierken in their production process, use this technique as a standard for their waterproof lines. Always confirm that a factory offers fully taped seams, not just critical seam taping.

3. Waterproof Zippers (e.g., YKK AquaGuard®)

Standard zippers have gaps between the teeth where water can seep through, especially under pressure. A waterproof zipper is engineered to eliminate this.

Function: Zippers like the renowned YKK AquaGuard® feature a proprietary coating on the back of the zipper tape and a special laminated flap that covers the teeth from the inside. This creates a seal that is both watertight and highly durable, resisting wear and tear from repeated opening and closing.

Value: This feature protects the main compartments, ensuring that even when zipped, no moisture can penetrate. It’s a hallmark of quality and a key detail to look for when selecting a waterproof bag factory for your project. For laptop compartments or valuable electronics storage, this is an absolute necessity.

4. Roll-Top Closure

Inspired by dry bags used in kayaking and rafting, the roll-top closure is one of the most effective ways to seal a main compartment.

Function: The user folds the top of the bag over itself three to five times, then buckles or clips it shut. This creates a long, tortuous path for water, making it virtually impossible for water to enter without immersion pressure. The more you roll it, the more secure it becomes.

Value: It offers adjustable capacity—you can pack the bag full and roll it down a little, or if it’s half-empty, you can roll it further down for a more compact and secure seal. This design is superior to a drawstring and flap cover in wet conditions.

5. Drainage Vents

While keeping water out is the primary goal, it’s also important to let accumulated water out. This is particularly relevant for packs used in marine environments or for sweaty hydration bladders.

Function: Small, strategically placed grommet holes at the bottom of a backpack or specific compartments allow any trapped water (from condensation, a leaking bottle, or splashes) to drain away freely.

Value: Drainage vents prevent the accumulation of water inside the bag, which can lead to mold, mildew, and added weight. It also helps in quickly drying the bag’s interior if it does get wet inside.

6. Reflective Elements and Accents

Safety is a critical feature that should never be an afterthought, especially for backpacks used by cyclists, commuters, or night-time hikers.

Function: Integrated reflective strips, logos, or piping on the backpack’s surface reflect light from car headlights or street lamps, making the user highly visible in low-light conditions.

Value: This dramatically increases user safety. For corporate clients creating branded backpacks for event participants or employees, it’s a feature that demonstrates care for the user’s well-being. These elements can be seamlessly incorporated into the customized logos and color schemes.

7. Dedicated and Multi-Functional Compartments

Organization is key to user satisfaction. A single, cavernous compartment is frustrating. Smart compartmentalization enhances functionality.

Function: This includes padded sleeves for laptops and tablets, zippered mesh pockets for small items, external tool loops, and separate dry/wet bags. Some designs even feature a separate compartment for shoes or wet gear.

Value: It allows for logical and secure storage of belongings, preventing damage from items knocking into each other. It saves time and reduces frustration for the user. When discussing your hiking bag OEM design, consider the specific gear your target audience carries to inform these compartment designs.

8. Ergonomic Carrying System

A backpack can be 100% waterproof, but if it’s uncomfortable to carry, it will stay in the closet. The carrying system is what connects the pack to the user.

Function: This encompasses the back panel (often padded and ventilated with mesh), the shoulder straps (contoured, padded, and adjustable), and a sternum strap and hip belt (to distribute weight from the shoulders to the stronger core and hip muscles).

Value: An ergonomic system makes heavy loads feel lighter and allows for better airflow, reducing back sweat and fatigue. This is crucial for any pack designed for extended use, like those from weierken, which are built for adventure. A good factory will offer different carrying system options based on the intended load and activity.

9. Abrasion-Resistant Bottom Reinforcements

The bottom of a backpack takes the most abuse—it’s set down on rough ground, dragged across surfaces, and is generally the first area to show wear.

Function: Using a higher denier (thicker) fabric or a different, more rugged material (like a ballistic nylon or a rubberized coating) on the bottom panel significantly increases the backpack’s durability.

Value: This reinforcement prevents punctures, scuffs, and tears, dramatically extending the backpack’s lifespan. It protects the waterproof integrity of the bottom of the bag, which is most vulnerable to physical damage.

10. Customized Logos and Color Schemes

This is where your vision comes to life. Branding transforms a generic, high-quality backpack into your custom product.

Function: This can be achieved through techniques like screen printing, heat transfer, or laser cutting for logos, and using a wide palette of colored fabrics and components (zippers, webbing) during the manufacturing process.

Value: Effective branding builds recognition, promotes your organization, and creates a sense of unity for teams or event attendees. A professional waterproof backpack manufacturer will have a design team to help you integrate your branding aesthetically and durably, ensuring it doesn’t compromise the fabric’s waterproof qualities.

Frequently Asked Questions (FAQs)

Q1: How is “waterproof” different from “water-resistant”?

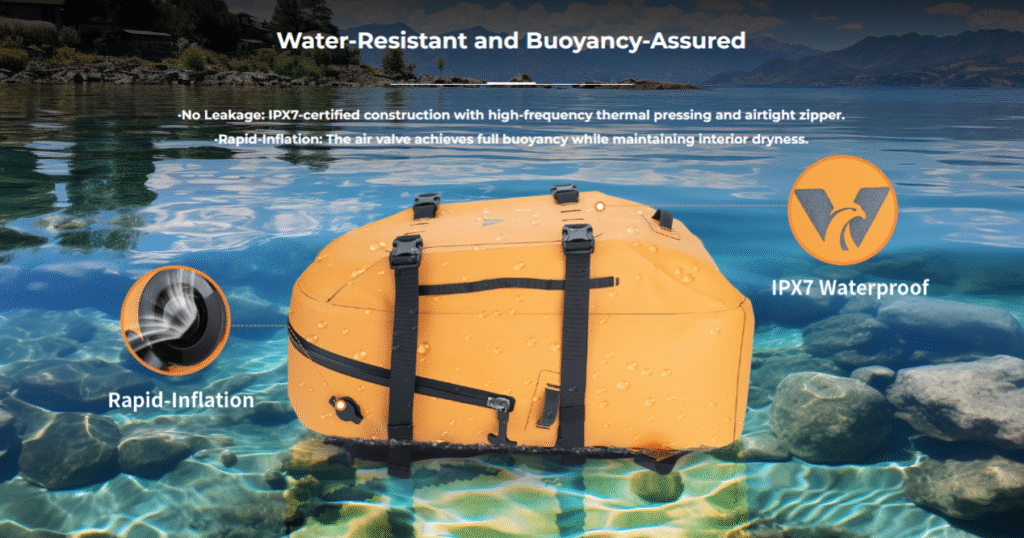

A: This is a crucial distinction. Water-resistant means a bag can withstand light rain or splashes for a short time, often through a surface coating. A truly waterproof backpack, like those manufactured to IP (Ingress Protection) standards, uses sealed materials and construction (taped seams, waterproof zippers) to prevent water from entering even under sustained heavy rain or during brief submersion.

Q2: Can I add a hydration bladder to a custom waterproof backpack?

A: Absolutely. Most professional hiking bag OEM designs include a dedicated hydration bladder compartment with a hose port. It’s vital to ensure the port is designed to be weather-resistant, often featuring a magnetic or covered closure to prevent water from entering through the hose exit point.

Q3: What is the typical lead time for a custom order from a waterproof bag factory?

A: Lead times can vary significantly based on the order’s complexity and quantity. A standard custom order can take anywhere from 4 to 12 weeks. This includes time for prototyping, sample approval, material sourcing, production, and quality control. It’s always best to initiate discussions with your chosen manufacturer well in advance of your deadline.

Q4: Are these backpacks suitable for activities beyond hiking, like commuting or cycling?

A: Yes, the principles of dry protection and durable organization are universal. A well-designed custom waterproof backpack is ideal for cycling commutes, urban travel, photography, watersports, and as emergency kits. The features like reflective elements for safety and dedicated laptop compartments make them incredibly versatile for daily use.

Q5: How do I maintain and clean my custom waterproof backpack to ensure it lasts?

A: Proper care is essential. Use a soft brush and mild soap to clean the surface, and rinse thoroughly. Avoid harsh detergents, washing machines, and dryers, as these can degrade seals, coatings, and laminates. After cleaning, air dry the backpack completely away from direct heat. For bags with a DWR coating on non-laminated areas, a technical fabric revitalizer can be used to restore water beading. Always follow the specific care instructions provided by your manufacturer.