An email arrived with disappointing news—again. Another shipment of delivery bags had failed quality inspection, this time due to inconsistent stitching and waterproofing failures. The brand had chosen their Delivery Bag Factory based primarily on cost, overlooking critical technical capabilities and communication protocols. The result: $25,000 in wasted inventory and missed delivery deadlines for their corporate clients.

This scenario plays out repeatedly when brands approach manufacturing as a transactional relationship rather than a technical partnership. Through managing production relationships with over 40 factories across Asia, I’ve identified seven critical strategies that separate successful collaborations from costly failures. Whether you’re launching a new delivery service or expanding your retail packaging solutions, these insights will help you navigate the complexities of working with a Delivery Bag Factory effectively.

Seven Essential Strategies for Successful Cooperation with Delivery Bag Factories

1. Technical Package Preparation: The Foundation of Manufacturing Accuracy

Your technical package serves as the manufacturing blueprint—ambiguous specifications inevitably lead to production errors and cost overruns. A comprehensive tech pack should include these critical elements:

Design Specifications

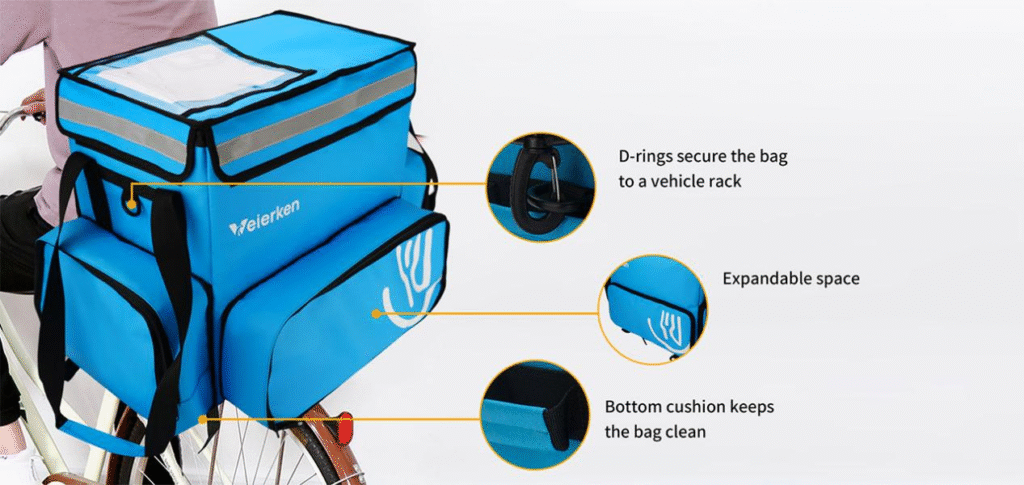

Provide detailed technical drawings with annotated dimensions, including tolerance ranges for critical measurements. For delivery bags, this includes not just overall dimensions but specific compartment sizes, strap lengths, and closure mechanisms. Include 3D renderings or isometric views to clarify complex construction elements. Weierken’s engineering team typically requests CAD files with layer separation for different materials and components, enabling precise pattern making and material calculation.

Material Breakdown Structure

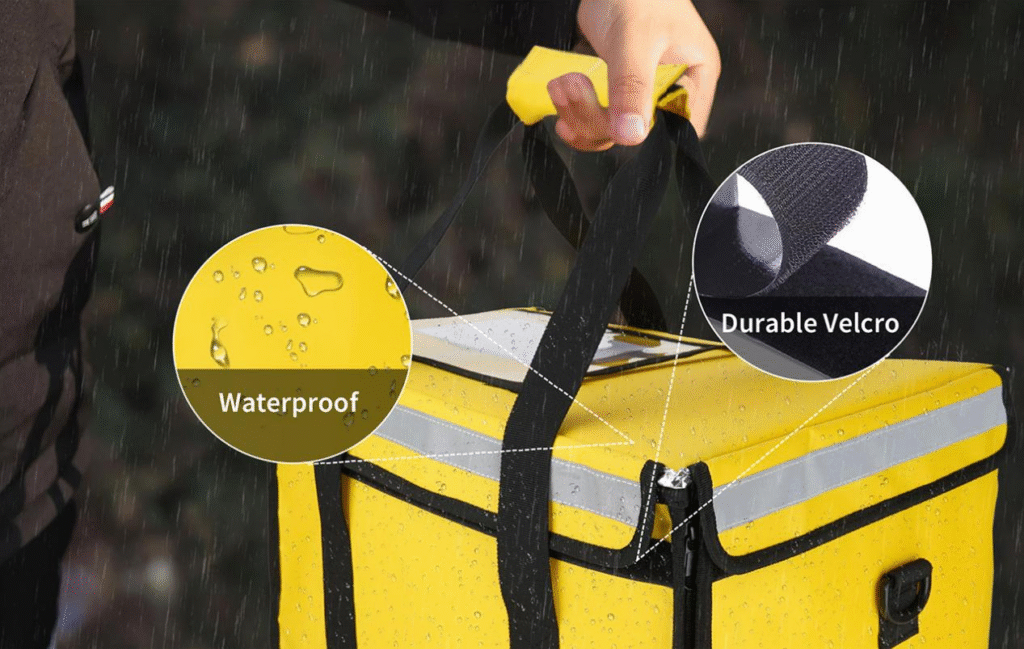

A comprehensive bill of materials should specify each component with technical references, including material composition, weight, thickness, and color standards. For delivery bags, this includes main body fabric, lining materials, waterproof coatings, zippers, buckles, stitching thread, and reinforcing elements. Reference specific material grades (e.g., 600D polyester with PU coating 2000mm water resistance) rather than generic descriptions. Weierken maintains a material library with standardized specifications that clients can reference to ensure clarity.

Construction Methodology

Detail specific manufacturing techniques required for each bag component. This includes stitch types (single needle, double needle, safety stitch), stitch density (stitches per inch), seam types (French seam, flat fell seam, bound seam), and reinforcement methods (bar tacks, rivets, reinforcing patches). For waterproof delivery bags, specify seam sealing methods and quality standards. Weierken’s technical team provides clients with a construction checklist that identifies critical stress points and recommended reinforcement methods based on the bag’s intended use.

2. Cost Structure Transparency: Understanding What You’re Paying For

Manufacturing quotes often obscure true costs through ambiguous categorization. Insist on transparent cost breakdowns to identify potential savings and avoid hidden charges:

Tooling and Mold Costs

One-time tooling expenses include cutting dies, specialized press forms, and custom hardware molds. For delivery bags with unique shapes or specialized components, these costs can represent significant initial investment. A professional Delivery Bag manufacturer should provide detailed tooling cost breakdowns with specifications for each item. Weierken typically amortizes tooling costs across the first production order, with ownership transferring to the client upon full payment.

Material Cost Calculations

Material costs should be calculated based on actual consumption patterns rather than estimated percentages. Request detailed material utilization reports showing how each component is nested for cutting to minimize waste. For delivery bags, material costs typically represent 45-60% of the total manufacturing cost, depending on complexity and order volume. Weierken’s quoting system provides clients with material consumption calculations that show exactly how much material each bag requires, enabling accurate cost forecasting for future orders.

Process and Labor Costs

Manufacturing processes should be costed individually, including cutting, sewing, waterproof treatment, quality control, and packaging. Labor costs should reflect the actual time required for each manufacturing step rather than blanket estimates. Weierken’s transparent costing model breaks down each manufacturing process with time studies and corresponding labor costs, enabling clients to understand exactly where their manufacturing dollars are allocated.

3. Sampling Protocol: The Stepped Validation Process

The sampling process represents your primary quality assurance mechanism before mass production. Implement a rigorous three-stage sampling protocol:

Prototype Samples

Initial prototypes verify design concept, functionality, and basic construction. At this stage, focus on overall dimensions, compartment layout, strap placement, and basic functionality. Materials may be substituted with equivalents for cost and availability. Weierken typically produces 3-5 prototype samples for client evaluation, with focus on design validation rather than final material selection.

Pre-Production Samples

These samples use actual production materials and represent the final product in all specifications. Evaluate material quality, color accuracy, hardware functionality, and construction integrity. Conduct rigorous performance tests, including weight capacity, water resistance, and durability assessments. Weierken’s pre-production samples include material swatches and component samples for client verification and archive purposes.

Production Samples

Randomly selected from the first production batch, these samples confirm that mass production maintains the quality standards established during pre-production. Verify consistency across multiple units and assess any variations introduced during scale-up. Weierken provides production samples with full inspection reports and recommends third-party verification for critical quality parameters.

4. Production Capacity Alignment: Matching Volume to Capability

Manufacturing efficiency depends on aligning your order volume with the appropriate production system:

Small Batch Specialty Lines

For orders of 500-2,000 units, specialized production cells with experienced operators provide the flexibility and attention to detail required for complex designs. These lines typically complete 50-100 units daily with extensive quality checks between processes. Weierken’s small batch lines employ senior technicians who handle multiple production stages, maintaining consistency through personal oversight rather than systemized processes.

Medium Volume Modular Systems

Orders of 2,000-10,000 units benefit from modular production systems that balance efficiency with flexibility. These systems utilize specialized workstations with operators focusing on specific construction elements. Weierken’s modular lines typically produce 200-500 units daily with quality checkpoints at critical process transitions.

High Volume Production Lines

For orders exceeding 10,000 units, dedicated production lines with highly specialized equipment and optimized workflow provide maximum efficiency. These lines can produce 1,000-2,000 units daily with automated quality monitoring at key stages. Weierken’s high-volume facilities employ line balancing techniques that optimize workflow and minimize bottlenecks while maintaining consistent quality through standardized processes.

5. Communication Protocol: Establishing Clear Information Channels

Effective manufacturing partnerships require structured communication systems with defined protocols:

Technical Communication Channels

Establish dedicated channels for technical discussions, separate from commercial negotiations. Designate specific technical representatives from both organizations with authority to make decisions within their domains. Weierken assigns dedicated project engineers to each client, serving as single points of contact for all technical communications and ensuring consistent interpretation of specifications.

Progress Reporting Systems

Implement regular reporting schedules with standardized formats covering production milestones, quality metrics, and potential challenges. Digital platforms that provide real-time production status updates prevent surprises and enable proactive problem-solving. Weierken’s client portal provides 24/7 access to production status, quality reports, and inventory levels of key materials.

Issue Resolution Procedures

Define escalation paths and response timelines for quality issues, specification conflicts, and schedule changes. Formalize the process for documenting and addressing exceptions to prevent unresolved issues from affecting production. Weierken’s issue tracking system requires formal documentation of any specification deviations and client approval before proceeding with affected production lots.

6. Quality Assurance Integration: Building Quality Into the Process

Quality management should be integrated throughout manufacturing rather than applied as a final inspection:

In-Process Quality Control

Implement checkpoints at critical production stages where defects can be identified and corrected before subsequent processes compound the issues. For delivery bags, key checkpoints include material inspection, cutting accuracy, sewing quality, waterproof treatment application, and final assembly. Weierken’s production lines feature quality verification stations after each major process, with operators required to verify incoming quality before beginning their work.

Standardized Inspection Protocols

Develop clear acceptance criteria for visual, dimensional, and functional characteristics. Use standardized inspection tools, lighting conditions, and assessment methods to ensure consistent evaluation across different inspectors and production batches. Weierken provides clients with detailed inspection manuals that specify exactly how each quality parameter should be verified, including sample sizes and acceptable defect levels.

Testing and Validation Methods

Establish routine testing protocols for critical performance characteristics. For delivery bags, this typically includes weight capacity testing, water resistance verification, strap strength testing, and hardware durability assessment. Weierken’s in-house testing laboratory conducts destructive testing on random samples from each production lot to validate performance claims and identify potential failure modes before products reach customers.

7. Logistics and Supply Chain Coordination

Manufacturing efficiency means little if products don’t reach their destination as planned:

Production Planning Integration

Align production schedules with your logistics capabilities and market requirements. Consider seasonal shipping constraints, holiday closures, and inventory management strategies when planning production timelines. Weierken’s production planning team works closely with clients to optimize production schedules based on market launch dates and logistical considerations.

Packaging Specifications

Develop packaging specifications that protect products during transit while aligning with your brand standards and sustainability goals. Consider packaging efficiency to minimize shipping volume and costs. Weierken’s packaging engineering team can optimize packaging designs to reduce dimensional weight while maintaining product protection during logistics handling.

Documentation and Compliance

Ensure all shipping documentation, including certificates of origin, compliance documentation, and commercial invoices, is accurate and complete to prevent customs delays. Weierken’s shipping department specializes in preparing complete documentation packages for various destination countries, with particular expertise in European and North American markets.

Partnership Beyond Production

Successful manufacturing relationships for an OEM Delivery Bag transcend transactional interactions to become true technical partnerships. The most effective collaborations occur when brands and factories work as integrated teams with shared objectives and transparent communication. Manufacturers like Weierken have built their reputation by embracing this partnership model, contributing their engineering expertise and manufacturing intelligence throughout the entire development and production process for a high-performance OEM Delivery Bag.

The strategies outlined above provide a framework for establishing manufacturing relationships that deliver consistent quality, predictable costs, and reliable timelines. By investing in thorough preparation, transparent communication, and rigorous validation, brands can transform their approach to manufacturing from a necessary cost to a competitive advantage.

Frequently Asked Questions

Q1: What is the typical timeline from initial inquiry to production delivery?

A:The complete process typically requires 12-16 weeks, broken down as follows: 2-3 weeks for technical development and costing, 3-4 weeks for sampling and approval, 6-8 weeks for production, and 1-2 weeks for shipping. Weierken has compressed this timeline to 8 weeks for urgent projects through parallel processing and expedited material procurement, though this typically incurs premium costs.

Q2: How do factories calculate material requirements for cost estimates?

A:Professional factories use CAD-based nesting software to calculate exact material consumption for each component, adding waste factors based on material characteristics and cutting methods. Weierken provides clients with material utilization reports showing exactly how much material each bag requires and how components are nested to minimize waste.

Q3: What is the difference between prototype samples and pre-production samples?

A:Prototype samples verify design concept and functionality using equivalent materials, while pre-production samples use actual production materials and represent the final product in all specifications. Weierken recommends clients use prototype samples for design validation and pre-production samples for quality benchmarking before mass production.

Q4: How can we ensure color consistency across multiple production runs?

A:Maintain physical color standards with your manufacturer and specify acceptable color tolerance using standardized systems like Pantone or CNCS. Weierken maintains client color libraries with approved standards and conducts instrumental color measurement using spectrophotometers to ensure consistency across production batches and material lots.

Q5: What documentation should we expect from our manufacturing partner?

A:Comprehensive documentation should include: detailed technical packages, material certificates, production samples with inspection reports, pre-shipment inspection results, and compliance documentation. Weierken provides clients with complete documentation packages, including photographic evidence of production quality and test reports from their in-house laboratory.