For procurement managers and business decision-makers, placing a heavy duty bag bulk order is a significant operational decision. The cost per unit isn’t just a number on a quote; it’s a reflection of a complex interplay of factors that directly impact your bottom line and operational efficiency. Understanding these factors is crucial for making an informed purchase that delivers true value. Companies like Weierken, with extensive experience in industrial packaging, often guide their B2B clients through these very considerations to ensure they receive a product that meets both their technical and budgetary requirements.

Navigating the pricing structure for a large-scale purchase can be daunting. This article breaks down the five key elements that suppliers evaluate when calculating the cost for your bulk order of heavy-duty bags, empowering you to negotiate effectively and optimize your investment.

Material Selection and Cost Analysis: The Foundation of Pricing

The type of material you choose is, without a doubt, the most significant determinant of the final price in any heavy duty bag bulk order. It dictates not only the initial cost but also the bag’s performance, lifespan, and total cost of ownership.

Common Materials and Their Cost Implications

- Polyvinyl Chloride (PVC): Known for its excellent water resistance, durability, and clarity, PVC is a common choice. However, its cost can be volatile as it is tied to petroleum prices and environmental regulations. It offers a good balance of strength and flexibility but may not be the most eco-friendly option.

- Polyethylene (PE & HDPE): This is a versatile and widely used polymer. Low-Density Polyethylene (LDPE) is more flexible, while High-Density Polyethylene (HDPE) offers superior strength and rigidity. PE is generally less expensive than PVC and is recyclable, making it a cost-effective and increasingly popular choice for many industrial heavy-duty bag applications.

- Canvas (Fabric): Traditional canvas bags, made from cotton or polyester-cotton blends, are highly durable, breathable, and have a premium feel. They are often more expensive than plastic-based options due to the raw material and weaving process. Their cost is influenced by global cotton prices and the specific weight (oz/yd²) of the fabric.

- Polypropylene (PP): PP is a lightweight, strong, and resistant material often used in woven bulk bags (FIBCs). It’s generally less expensive than canvas and offers high tensile strength, making it ideal for transporting heavy, dry goods.

Durability, Weight, and Long-Term Value

A critical B2B consideration is the life-cycle cost. Opting for a cheaper, lower-grade material might reduce your initial bulk bag order cost, but if the bags fail quickly, the cost of frequent replacements and potential product loss will far outweigh the initial savings. A heavier, high-density fabric might have a higher unit price, but its extended service life provides better long-term value. Furthermore, evolving environmental standards may influence material choice; opting for recyclable or reusable materials can mitigate future regulatory costs and enhance your corporate sustainability profile.

Order Volume and Economic Discounts: The Power of Scale

The very nature of a heavy duty bag bulk order is to leverage quantity for better pricing. The relationship between order volume and unit cost is typically non-linear, meaning doubling your order doesn’t double the cost—it often significantly reduces the per-unit price.

Understanding Tiered Pricing and MOQs

Most suppliers operate on a tiered pricing model. For example:

- Tier 1: 1,000 – 4,999 units: $3.50/bag

- Tier 2: 5,000 – 9,999 units: $2.90/bag

- Tier 3: 10,000+ units: $2.50/bag

This structure reflects the supplier’s reduced per-unit setup and handling costs with larger runs. The Minimum Order Quantity (MOQ) is the smallest quantity a supplier is willing to produce economically. As a professional buyer, you should not just accept the standard MOQ. Negotiate based on your projected annual usage or the potential for a long-term partnership. A supplier like Weierken may offer flexible MOQs for standard products to accommodate the needs of growing businesses.

Leveraging Long-Term Contracts

For ongoing, predictable needs, consider a long-term supply agreement. This commits you to purchase a certain volume over 6, 12, or 24 months, allowing the supplier to plan raw material purchases more efficiently and secure better rates, a portion of which is passed on to you. This strategy is excellent for locking in favorable pricing and ensuring a consistent supply of durable bulk bags for your operations.

Customization and Value-Added Services: Identifying Hidden Cost Drivers

While standard bags are cost-effective, most businesses require some level of customization. This is where the price can diverge significantly from the base model. Understanding these cost drivers is essential for budgeting and avoiding surprises.

Common Customization Elements

- Logo Printing: The process (screen printing, heat transfer, digital printing), number of colors, and print area size all affect cost. A simple, one-color logo is inexpensive, while a complex, multi-color, full-side print requires more setup time and ink, increasing the price.

- Special Sizes and Designs: Moving away from standard dimensions requires new cutting dies and potentially adjustments to the production line, incurring one-time engineering and setup fees (often called a “tooling charge”).

- Color Matching: Requesting a specific Pantone color, rather than a standard in-stock color, involves additional cost for custom pigment mixing.

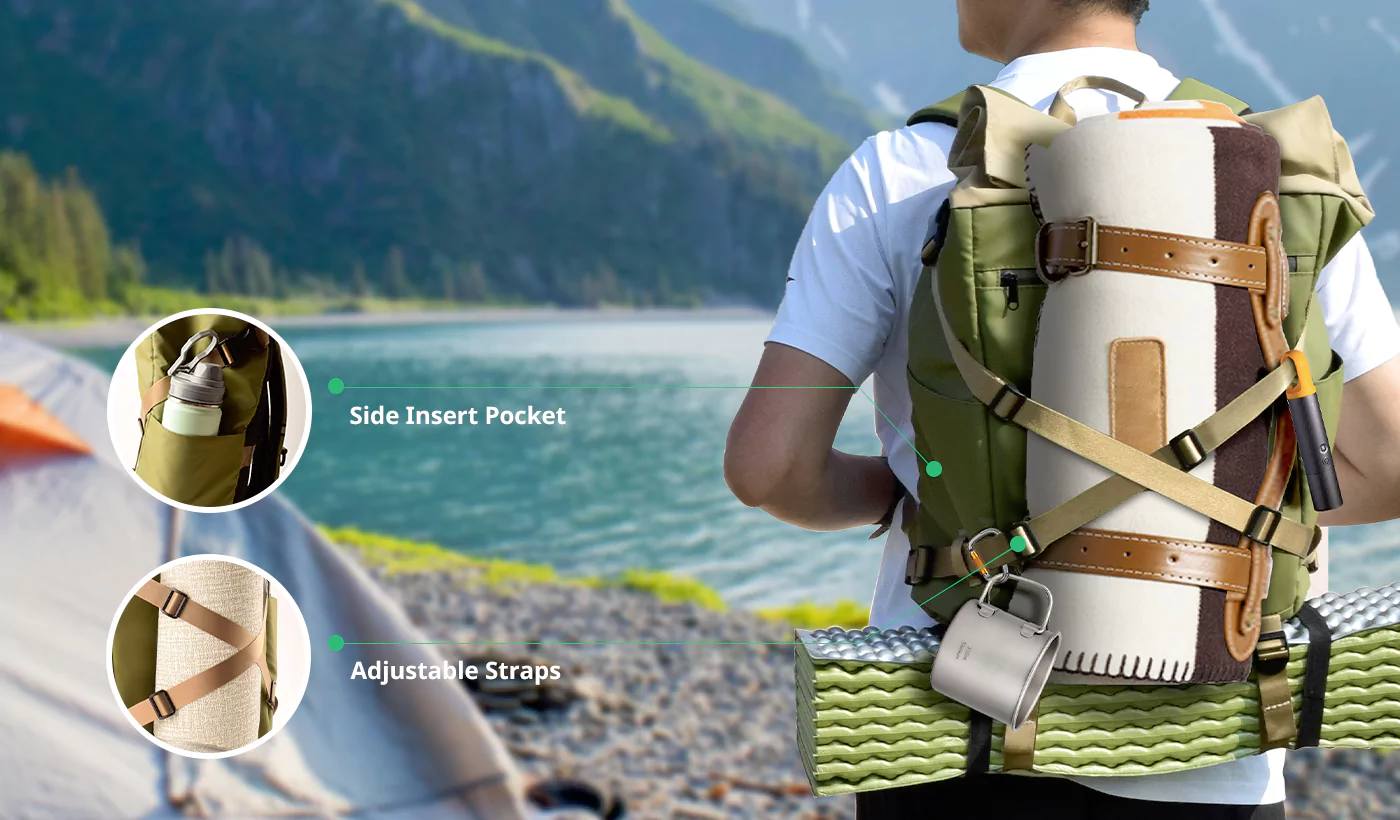

- Additional Features: Elements like reinforced stress points, special gussets, unique zippers, or internal pockets add extra manufacturing steps and material, incrementally increasing the unit cost.

The Cost of Added Services

Beyond physical customization, ancillary services contribute to the final quote. Rigorous Quality Control (QC) protocols, specialized packaging for shipment, and design consultancy are all value-added services that require labor and expertise. When evaluating a supplier, clarify what is included in the base price and what is considered an add-on. A reliable partner will transparently break down these costs, helping you make smart choices about which customizations are essential for your custom heavy duty bag bulk order.

Production Process and Technical Investment: Balancing Efficiency and Cost

The manufacturing methodology behind your heavy duty bag bulk order is a major, though often overlooked, cost component. The level of automation and the specific techniques used directly influence both the speed of production and the consistency of the final product.

Sewing vs. Welding and Other Techniques

- Sewing: Traditional sewing with industrial threads is versatile and strong, suitable for fabrics and some plastics. The cost depends on stitch density, thread type, and the complexity of the seams. Manual sewing is labor-intensive, while automated sewing lines are faster but require significant capital investment.

- Welding (Heat Sealing): This is the primary method for joining thermoplastic materials like PVC, PE, and PP. High-frequency welding or ultrasonic welding creates a seamless, waterproof bond. The process is highly automatable and fast, often leading to a lower unit cost for high-volume runs of synthetic bags. The initial investment in welding machinery is high, but the operational efficiency benefits large bulk orders.

The Automation Factor

A manufacturer with a high degree of automation can produce large quantities of consistent quality at a lower labor cost per unit. However, this efficiency is often realized best with standard or minimally customized orders. Highly complex, custom designs may require more manual intervention, slowing down the line and increasing cost. When assessing a supplier’s quote, consider their technological capabilities. A company like Weierken that invests in modern production equipment is likely to offer a more competitive price for a standard heavy duty bag bulk order while maintaining high-quality standards.

Supply Chain and Logistics Factors: The End-to-End Impact

The final price you pay is influenced by factors that extend far beyond the factory floor. A globalized supply chain means that raw material sourcing, production location, and logistics complexity play a substantial role in the total landed cost.

Raw Material Sourcing and Production Cycles

The geographic source of raw polymers or fabrics affects their cost. Tariffs, trade agreements, and global commodity fluctuations directly impact your quote. Furthermore, the production lead time is a critical factor. A rushed order may require expedited raw material shipping or overtime labor for the production team, both of which carry premium charges. Planning your bulk order of heavy-duty bags well in advance allows the supplier to optimize their production schedule and material procurement, resulting in a more favorable price for you.

Logistics, Warehousing, and Final Delivery

How your finished bags are stored and shipped is a final cost variable. Are you ordering FOB (Free on Board) from the factory, meaning you handle the main international shipping, or is it a DDP (Delivered Duty Paid) quote? For massive orders, the cost of container shipping, insurance, and import duties can be significant. Consolidating orders, using economical shipping methods, and efficient warehouse management on the supplier’s end (like Weierken‘s optimized inventory systems for repeat clients) can all help mitigate these costs. Efficient supply chain management on their part translates into direct savings for your heavy duty bag bulk order.

Making an Informed Bulk Order Decision

The cost of a heavy duty bag bulk order is a multifaceted equation, blending material science, volume economics, customization, production engineering, and global logistics. By developing a deep understanding of these five key factors—Material, Volume, Customization, Production, and Supply Chain—you transition from a passive price-taker to an strategic procurement partner.

This knowledge allows you to ask the right questions, negotiate from a position of strength, and ultimately select a supplier who offers not just the lowest price, but the best overall value. It’s this commitment to transparent, value-driven partnerships that has allowed companies like Weierken to build long-term relationships with their B2B clients, ensuring that every heavy duty bag bulk order is a smart investment in operational resilience.

Frequently Asked Questions (FAQs) About Heavy Duty Bag Bulk Orders

Q1: What is the typical lead time for a large heavy duty bag bulk order?

A1: Lead times can vary significantly based on order complexity, customization, and the supplier’s current production schedule. For a standard, large heavy duty bag bulk order, you can typically expect a lead time of 4 to 8 weeks. This includes time for material procurement, production, quality control, and shipping. Highly customized orders or those placed during peak seasons may take longer.

Q2: Can we request samples before placing the full bulk order?

A2: Yes, and you absolutely should. Reputable suppliers understand that B2B clients need to verify quality before committing to a large purchase. Most companies, including Weierken, are willing to provide production samples for a nominal fee. This allows you to check the material, construction, and any customization firsthand, ensuring the final product meets your specifications for your industrial heavy-duty bag needs.

Q3: How does the MOQ (Minimum Order Quantity) work for custom designs?

A3: The MOQ for custom designs is almost always higher than for standard stock bags. This is because custom orders require unique setup, including creating new printing screens, cutting dies, or programming for automated machines, which incurs upfront costs. The supplier sets the MOQ to ensure these setup costs are amortized over a sufficient number of units to keep the per-bag price reasonable. The exact MOQ is negotiable based on the design’s complexity.

Q4: Are there any hidden costs we should be aware of in a bulk order quote?

A4: A professional quote should be transparent, but it’s crucial to confirm what is included. Ask specifically about:

- Tooling/Mold Fees (for non-standard designs)

- Cost of sample production and shipping

- Packaging for shipment (e.g., cartons, pallets)

- Freight and insurance costs (FOB vs. DDP)

- Payment transaction fees

Clarifying these points upfront for your custom heavy duty bag bulk order will prevent unexpected charges later.

Q5: What sustainable or eco-friendly material options are available for heavy-duty bags?

A5: The market for sustainable materials is growing rapidly. Common options for a heavy duty bag bulk order include Recycled Polyethylene (rPE) or Recycled Polypropylene (rPP), which are made from post-consumer or post-industrial waste. Biodegradable additives are another option, though their effectiveness depends on specific disposal conditions. Additionally, fabrics like organic canvas or jute are natural alternatives. Discuss your sustainability goals with your supplier; they can advise on the best balance of eco-friendliness, durability, and cost for your bulk order of heavy-duty bags.