For business buyers, procuring hiking bags in bulk is a significant decision that impacts branding, operational efficiency, and cost management. Whether for corporate gifts, team-building events, or retail distribution, a well-executed hiking bag bulk order requires strategic planning. This guide delves into the critical factors for B2B procurement, helping you navigate from supplier selection to final delivery.

Key Decision-Making Factors for B2B Procurement

When placing a bulk order for hiking bags, several non-negotiable elements influence the decision. Quality, cost, and reliability sit at the top of the list, but digging deeper reveals more.

First, consider the end-user. Are these bags for employees, promotional giveaways, or resale? The answer shapes your priorities. For corporate gifts, aesthetics and branding might lead; for outdoor teams, functionality and durability are paramount. Secondly, evaluate the total cost of ownership. The cheapest unit price might hide flaws in craftsmanship, leading to higher return rates or reputational damage. Finally, assess the supplier’s capacity for consistency. Can they replicate the same quality across multiple production runs? For instance, partnering with a specialist like weierken, known for rigorous quality control, can mitigate long-term risks.

How to Evaluate Cost-Effectiveness in Bulk Purchasing

Calculating the true cost of a hiking bag bulk order goes beyond comparing price tags. Here’s a structured approach:

- Break Down the Cost Structure: Analyze material costs, labor, customization charges (e.g., logo printing), logistics, and import duties. A detailed quote prevents unexpected expenses.

- Calculate Cost-Per-Use: A slightly more expensive bag built with robust materials like 600D polyester will outlast a cheaper alternative, offering better value over time.

- Factor in Customization Expenses: Simple logo embroidery is cost-effective, while all-over printing or unique color matching increases the price. Weierken’s design team often advises clients on achieving brand impact within budget.

- Consider Minimum Order Quantity (MOQ): Higher MOQs usually mean lower per-unit costs. Balance this against your storage capabilities and demand forecasts to avoid overstocking.

Matching Material, Capacity, and Functionality with Usage Scenarios

A one-size-fits-all approach doesn’t work for hiking bag bulk purchases. Aligning the product specs with the intended scenario is crucial for satisfaction.

- Corporate Gifts & Promotional Items:

- Scenario: Short walks, daily commutes, brand visibility.

- Recommendation: 20-30L capacity, lightweight polyester or recycled materials, simple compartments. Focus on a sleek design for easy logo imprinting.

- Team Building & Company Retreats:

- Scenario: Day hikes, requiring carrying water, food, and basic gear.

- Recommendation: 30-50L capacity, durable nylon or polyester with water-resistant coatings. Look for features like hydration bladder compatibility, sternum straps, and multiple pockets.

- Adventure Sports & Event Kits:

- Scenario: Demanding outdoor activities, potentially adverse weather.

- Recommendation: 50L+ capacity, high-denier ripstop nylon, fully waterproof (e.g., TPU laminate), reinforced stitching, and advanced frame support systems.

Supplier Screening and Factory Audit Process

Vetting your manufacturer is perhaps the most critical step in securing a reliable hiking bag bulk order.

- Initial Screening: Check business licenses, export history, and online presence. Look for certifications like ISO 9001 or BSCI, which indicate standardized management.

- Sample Evaluation: Request physical samples to inspect stitching, zipper quality, fabric feel, and overall craftsmanship.

- Factory Audit: If order volume is significant, conduct an on-site or virtual audit. Key areas to assess include:

- Production Lines: Are they organized and efficient?

- Quality Control Stations: Is there in-process inspection?

- Working Conditions: Ethical practices often correlate with product quality.

- Material Storage: How are raw materials handled and stored?

Weierken, for example, welcomes client audits and virtual factory tours, demonstrating transparency in their production process from cutting to packing.

Customization Services: Creating Brand-Exclusive Hiking Bags

Customization transforms a generic bag into a powerful brand asset.

- LOGO Printing and Color Customization: Options range from embroidery (premium and durable) to silkscreen printing (vibrant for large areas). Some suppliers, including weierken, offer color-matching services to align with your brand’s Pantone codes.

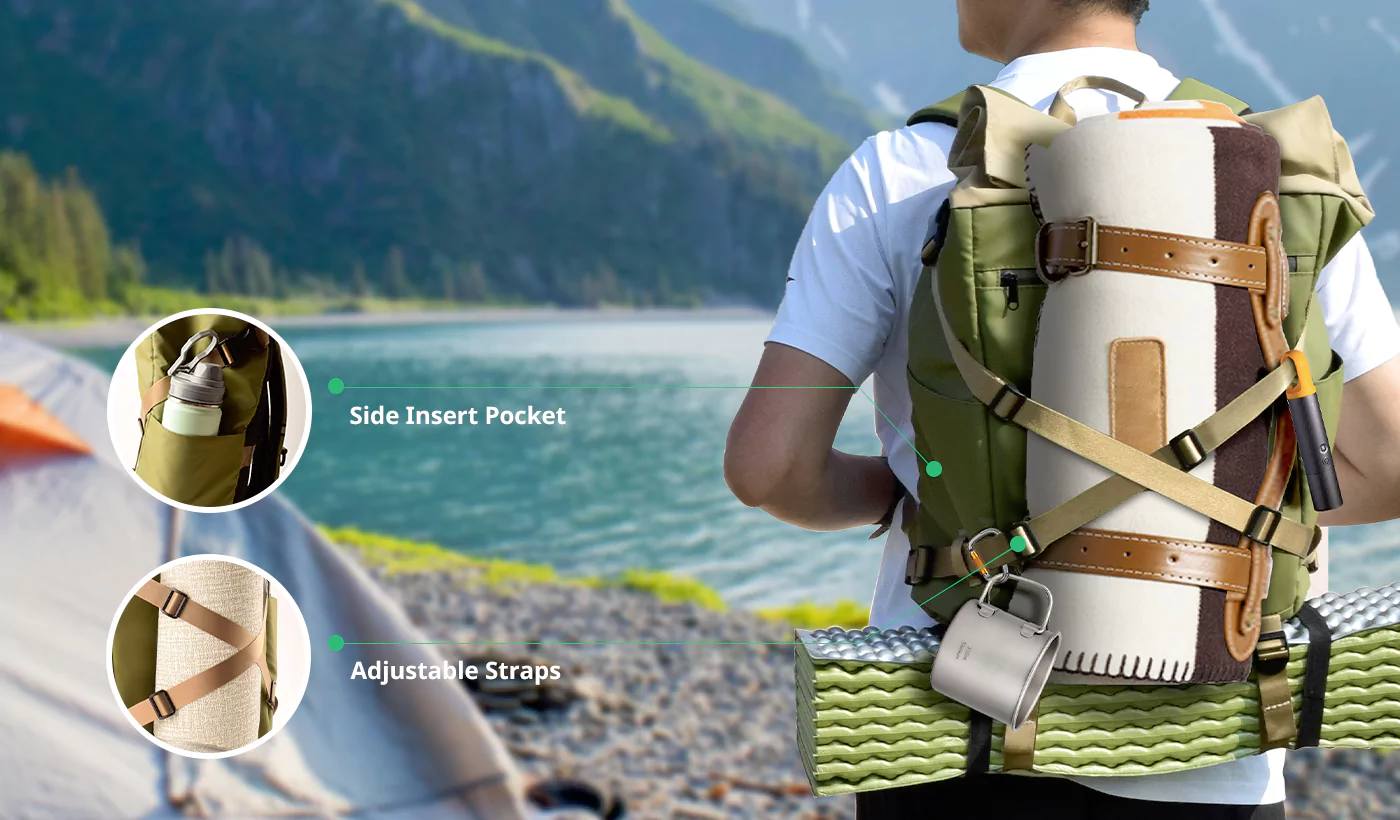

- Adding/Removing Functional Modules: Based on your needs, you can add laptop sleeves, RFID-protected pockets, or detachable waist belts. Conversely, removing unnecessary features can help reduce costs for simpler giveaways.

- Balancing Small-Batch Customization and Mass Production: For testing the market or fulfilling a small corporate order, explore suppliers offering low MOQ for custom hiking bags. For large-scale production, plan well ahead to integrate into the main production schedule efficiently.

Supply Chain and Delivery Management

Production Cycle and Scheduling for Bulk Orders

A typical hiking bag bulk order production cycle is 45-90 days, depending on complexity and order volume. This timeline includes raw material sourcing, production, quality control, and shipping preparation. Once an order is confirmed with a supplier, they should provide a detailed production schedule, outlining key milestones like fabric cutting, assembly, and final inspection.

Managing Peak Season Demand and Rush Orders

Peak seasons (e.g., before summer or holidays) strain production capacity. To avoid delays:

- Plan and Forecast Early: Place orders 4-6 months in advance.

- Build Relationships: Long-term partners often prioritize reliable clients.

- Explore Rush Options: Some suppliers can expedite production for a fee, but this may impact cost. Weierken maintains a flexible production line to accommodate a degree of urgent hiking bag bulk order requests.

Logistics Solutions: Sea Freight, Air Cargo, Cross-Border Logistics

- Sea Freight: The most cost-effective for large, non-urgent orders. Transit time can be 4-8 weeks.

- Air Cargo: Ideal for samples and small, high-value urgent shipments. Much faster but significantly more expensive.

- Cross-Border Logistics: Work with suppliers who have experience in handling export documentation, customs clearance, and final-mile delivery to your warehouse.

Market Trends and Customer Demand Analysis

Procurement Characteristics in Outdoor, Corporate, and Education Sectors

- Outdoor Industry: Prioritizes technical performance, innovation, and weight-to-strength ratio.

- Corporate Sector: Focuses on brand alignment, aesthetic appeal, and value for money. Bulk purchase of hiking bags for corporate gifts is a growing trend.

- Education & Training: Looks for durability, safety, and practicality, often needing bags that can withstand frequent use.

The Rise of Eco-Friendly Materials and Sustainable Procurement

A significant shift is towards using recycled fabrics (e.g., rPET), bluesign® certified materials, and PFC-free water repellents. Buyers are increasingly asking suppliers for their sustainability policies and material traceability.

Market Acceptance of Integrated Smart Features

Features like integrated power banks, USB charging ports, and advanced waterproofing (e.g., welded seams) are moving from niche to mainstream. However, their value depends on the target audience. For a corporate client, a charging port might be a welcome addition; for a hardcore hiking group, reliability of core functions remains paramount.

Quality Control and After-Sales Guarantee

Inspection Standards: AQL Sampling and Functional Tests

Adopting the AQL (Acceptable Quality Level) standard is industry best practice. For hiking bag bulk orders, inspectors randomly select samples from the production batch to check for defects in workmanship, materials, and function.

Functional tests should include:

- Zipper and buckle strength tests.

- Strap pull tests.

- Waterproofness tests (if applicable).

- Load-bearing capacity tests.

After-Sales Support and Return Policy

Clarify the warranty period and the policy for defective products. A reputable supplier should offer a clear policy for replacing defective items within a specified timeframe. Weierken typically provides a 12-month warranty against manufacturing defects.

Managing Quality Stability for Long-Term Cooperation

For ongoing partnerships, implement a scorecard system to track the supplier’s performance on quality, on-time delivery, and communication. Regular quality audits and open feedback loops help maintain high standards.

Exploring Cooperation Models

The OEM/ODM Cooperation Process

- OEM (Original Equipment Manufacturing): You provide the complete design and specifications, and the manufacturer produces it for you.

- ODM (Original Design Manufacturing): The manufacturer offers existing designs that you can customize.

The process generally flows: Inquiry -> Quotation -> Negotiation & Contract Signing -> Sample Development & Confirmation -> Mass Production -> QC & Shipping.

Sample Confirmation and Prototyping Lead Time

Always insist on approving a pre-production sample before mass production begins. This step ensures all customization details are correct. The prototyping cycle usually takes 10-20 days.

Payment Terms and Contract Clauses

Common payment terms are:

- 30-50% deposit with order, balance before shipment.

- T/T (Telegraphic Transfer) or L/C (Letter of Credit) for larger orders.

The contract should explicitly detail product specifications, quality standards, delivery date, payment terms, intellectual property rights, and liability for breaches.

Frequently Asked Questions (FAQ)

Q1: What is the typical Minimum Order Quantity (MOQ) for a custom hiking bag bulk order?

A: MOQs vary significantly by supplier. For standard models with simple logo printing, it can be as low as 100-500 pieces. For fully customized designs involving unique fabrics or features, MOQs can start from 1,000 pieces or more. It’s best to discuss your specific needs directly with manufacturers like weierken to find a flexible solution.

Q2: How long does the entire process take from order placement to delivery for a large hiking bag bulk purchase?

A: For a standard custom order, you should budget 60 to 90 days. This includes approximately 30-45 days for production and another 15-30 days for sea freight shipping. Complex customizations or peak seasons can extend this timeline, so early planning is essential.

Q3: What are the key quality checks I should request for my hiking bag bulk order?

A: Insist on a third-party Pre-Shipment Inspection based on AQL standards. Key checks include material conformity, stitch quality (no skipped stitches or loose threads), zipper and buckle functionality, strap strength, load test, and accuracy of logo printing/embroidery. A professional inspection report is crucial.

Q4: Can we use our own unique designs and fabrics for an ODM project?

A: Absolutely. In an ODM model, while the manufacturer provides the base designs, you can request significant modifications, including using specific, sourced fabrics. You will need to provide fabric specifications or samples, and the factory will assess feasibility and cost.

Q5: What are the most cost-effective customization options for a promotional hiking bag bulk order?

A: For maximizing budget on promotional items, focus on silkscreen printing for logos (rather than embroidery) and using the supplier’s existing color palettes for fabric. Choosing a standard, high-volume model from their catalog without structural modifications is also the most cost-effective path for a bulk purchase of hiking bags.