You’re at a trade show, and a potential client hands you a custom IPX7 bag containing a high-end electronic device. They casually mention it survived a monsoon during transit. That’s not luck; that’s the precision of IPX7 waterproofing in action. For B2B decision-makers, understanding this standard isn’t just technical jargon—it’s a cornerstone of product reliability, client trust, and market differentiation. In industries where moisture is the nemesis, from outdoor gear to medical equipment, a custom IPX7 bag isn’t an accessory; it’s a shield. Let’s dive into what makes these bags a non-negotiable asset for businesses worldwide, and how brands like weierken are mastering this space with engineered solutions.

Demystifying the IPX7 Standard: From Technical Parameters to Real-World Applications

What Does IPX7 Really Mean?

The IPX7 rating isn’t a vague promise of “water resistance.” It’s a rigorous certification defined by the International Electrotechnical Commission (IEC). For a product to earn this badge, it must withstand immersion in up to 1 meter of freshwater for 30 minutes without leakage. Think of it as a simulated accidental drop into a pool or a puddle. The testing is done under controlled laboratory conditions, but its implications are profoundly practical. When you invest in a custom IPX7 waterproof bag, you’re buying into this verified level of protection.

IPX7 vs. Other Waterproof Ratings: Choosing the Right Shield

Not all waterproofing is created equal. Here’s a quick breakdown:

- IPX5/IPX6 (Jet Spray Protection): These bags resist powerful water jets from nozzles—ideal for kayaking or hiking in heavy rain. However, they aren’t designed for submersion.

- IPX7 (Immersion Protection): The sweet spot for most B2B applications. It guarantees survival during short, accidental dunks. This is the core protection offered by many reliable IPX7 dry bags.

- IPX8 (Extended Immersion): For deeper, longer submersion (details specified by the manufacturer). Essential for professional diving equipment but often overkill for general-purpose use.

Understanding this hierarchy ensures you don’t over-specify or under-deliver. An IPX7 waterproof bag is typically the most cost-effective and practical solution for protecting electronics and sensitive materials from everyday water hazards.

Real-World Validation of IPX7 Reliability

Lab tests are one thing; field performance is another. To trust a custom IPX7 bag, look for real-world validation. Reputable manufacturers like weierken often conduct additional stress tests, such as repeated open-close cycles and abrasion resistance checks on seals. For B2B clients, requesting sample batches for in-house testing—like a simple 30-minute soak test—is a standard due diligence step. The reliability of a custom IPX7 bag is proven when the contents emerge bone-dry, every single time.

Key Design and Manufacturing Considerations for Custom IPX7 Bags

Material Matters: TPU, PVC, and Nylon

The foundation of any waterproof bag is its material.

- TPU (Thermoplastic Polyurethane): A premium choice. It’s highly durable, flexible even in cold conditions, environmentally friendlier (often free of chlorides), and offers excellent clarity for transparent electronic cases. For a high-end custom IPX7 bag, TPU is often the go-to material.

- PVC (Polyvinyl Chloride): A cost-effective and robust option. It provides good waterproofing but can be stiffer and less eco-friendly. Ideal for heavy-duty industrial applications where absolute clarity isn’t a priority.

- Nylon Tarpaulin: Often coated with TPU or PVC, this material adds tremendous tear and abrasion resistance. It’s common in custom IPX7 dry bags meant for harsh outdoor environments like rock climbing or white-water rafting.

Structural Integrity: Seals, Seams, and Valves

Design is where waterproofing succeeds or fails.

- Sealing Mechanisms: Roll-top closures with interlocking clips are the gold standard, creating a multi-layer physical barrier. For hard cases, silicone gaskets and latch-lock systems are used.

- Seam Construction: This is critical. Stitched seams are punctures waiting to happen. High-frequency welding (HFW) or ultrasonic sealing melts the material at the seams, creating a homogenous, impenetrable bond. This is a non-negotiable feature for a reliable IPX7 dry bag.

- Pressure Equalization Valves: For bags used in changing altitudes (e.g., air travel), these one-way valves release internal air pressure without compromising the waterproof seal, preventing the bag from bloating or bursting.

Production Processes: The Art of Sealing

The chosen manufacturing process directly impacts quality and longevity.

- High-Frequency Welding (HFW): Uses electromagnetic energy to fuse materials. It creates incredibly strong, clean, and reliable seams, perfect for complex shapes in a custom IPX7 waterproof bag.

- Ultrasonic Sealing: Uses high-frequency sound waves to create friction and heat, bonding materials together. It’s fast and effective for specific material combinations.

B2B Applications and Market Demand Analysis

The versatility of the custom IPX7 bag makes it a cross-industry workhorse.

Electronics Accessories

From custom IPX7 bags for smartphones on a boating tour to protective casings for action cameras and drone controllers, this segment is a massive driver of demand. The focus here is on clarity, touch-screen functionality, and a snug fit.

Outdoor Sports Equipment

This is the classic domain of the IPX7 dry bag. Diving bags, river rafting storage, and hiking pouches protect everything from maps and food to emergency first-aid kits. Durability and lightweight design are paramount.

Industrial Protection

Sensitive industrial sensors, circuit boards, and medical diagnostic equipment are highly susceptible to moisture damage during transport or storage. A custom IPX7 waterproof bag acts as affordable, reliable insurance against costly corrosion and failure.

Promotional Gifts & Branded Merchandise

Companies are increasingly using custom IPX7 bags as high-value corporate gifts. A branded dry bag is practical, has a long shelf-life, and positions the giver as a brand that values quality and innovation—a step above the typical logoed pen. This is an area where weierken has helped many businesses create impactful branded solutions.

The Customization Process and Supply Chain Collaboration

From Prototype to Production: A Managed Flow

A successful custom IPX7 bag project hinges on a transparent, multi-stage process: Design Confirmation -> Material Sourcing -> Prototype Sampling -> Testing & Approval -> Mass Production -> QC & Shipping. Skipping rigorous prototype testing is a common pitfall. Always insist on receiving and thoroughly testing pre-production samples.

Communicating Your Custom Needs Effectively

Clarity is king when briefing a manufacturer. Be specific about:

- Dimensions: Provide precise internal and external measurements.

- Printing & Branding: Specify the print technique (screen printing, heat transfer) and provide high-resolution vector logos.

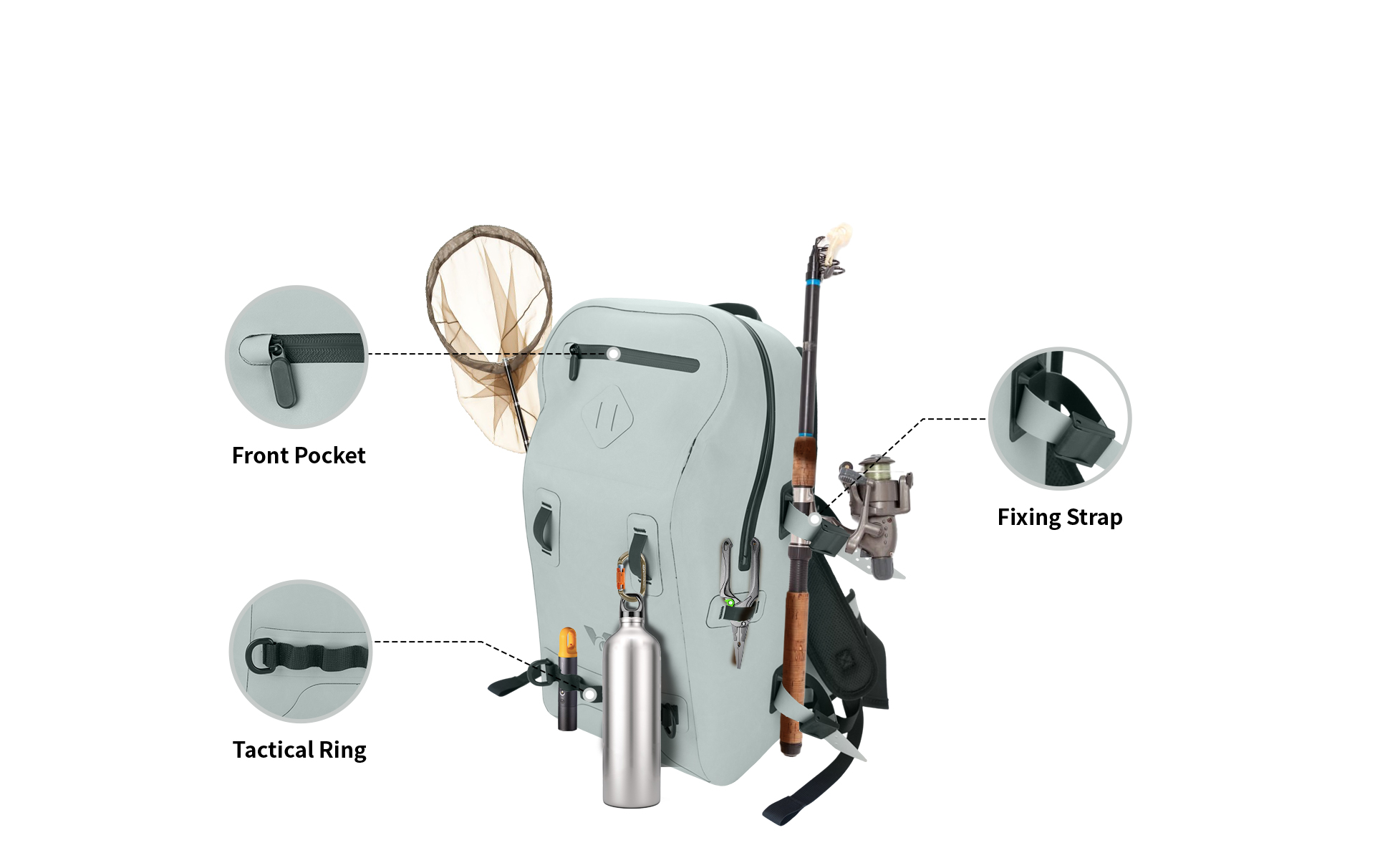

- Functional Features: Detail needed accessories—D-rings, carrying straps, transparent windows, zip-locks, etc.

Quality Control and Inspection Standards

Never leave quality to chance. A professional QC process involves:

- On-site Testing: Randomly selected units from the production line are subjected to air inflation tests (to check for pinhole leaks) or actual water immersion tests.

- Dimensional and Visual Checks: Ensuring the final product matches the approved sample in every detail, from stitch quality to color accuracy. Partnering with a manufacturer that has a transparent QC protocol, like weierken, is crucial for B2B success.

Market Trends and Future Innovations

The Rise of Eco-Conscious Materials

The demand for sustainable solutions is growing. We’re seeing increased use of recycled TPU and PVC, as well as bio-based polymers. Offering a “green” custom IPX7 waterproof bag is becoming a significant market differentiator.

The Smart, Reusable Dry Bag

Innovation is moving beyond basic protection. Think custom IPX7 bags integrated with advanced Dry-Tech moisture indicators, modular attachment systems, and designs engineered for hundreds of reuse cycles, moving them from a disposable item to a core piece of user gear.

E-commerce and Brand Globalization

The rise of cross-border e-commerce platforms has made it easier than ever for manufacturers to connect with global B2B clients. For brands looking to “go global,” a high-quality, reliable custom IPX7 bag is a universally understood product with strong demand across North American, European, and Asian markets.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of a custom IPX7 bag over a standard water-resistant bag?

A1: A custom IPX7 bag offers a certified, measurable level of protection against submersion, not just splashes. The IPX7 standard guarantees it can be immersed in 1 meter of water for 30 minutes. Standard water-resistant bags lack this rigorous certification and will likely fail if fully submerged, making the custom IPX7 waterproof bag a must for critical applications.

Q2: Can you print my company’s logo on a custom IPX7 dry bag?

A2: Absolutely. High-quality printing is a core part of the customization process. Techniques like screen printing or heat transfer are commonly used to apply logos and branding onto custom IPX7 bags without compromising the material’s waterproof integrity. It’s a fantastic way to enhance brand visibility with a practical product.

Q3: How long does it typically take to produce a custom IPX7 bag order from sampling to delivery?

A3: The timeline varies based on order complexity and quantity. Generally, the process—including sample development and approval (2-3 weeks), followed by mass production (4-6 weeks)—takes approximately 6-9 weeks. It’s always best to discuss your specific timeline with your manufacturer, like weierken, early in the process.

Q4: Are custom IPX7 bags reusable, or are they for single use?

A4: A well-made custom IPX7 bag is designed for multiple uses. The durability of materials like TPU and robust sealing mechanisms allow them to be opened, closed, and used repeatedly. Their longevity is a key reason they are so popular as branded corporate gifts and for outdoor sports.

Q5: How can I verify that my order of custom IPX7 bags truly meets the IPX7 standard?

A5: Reputable manufacturers will provide test reports from certified labs. For your own assurance, you can specify random batch testing as part of your quality control agreement. This involves selecting samples from the production run and subjecting them to a simple 1-meter, 30-minute immersion test to validate that every custom IPX7 waterproof bag you receive performs as promised.